Plan-E-Tech Industries Inc. - Made-in-USA Nail/Bolt Rolling Dies & Reworking Service for Global Customers

by Dean Tseng, Fastener World

Plan-E-Tech was started in 1984 by a small group of partners to produce planetary thread rolling dies for the nail industry, and then cylindrical and planetary thread rolling dies for bolt production. In 2007 they sold Plan-E-Tech to Fastener Industries Inc., a 100 percent employee-owned company. In 2008 Jim Kasper joined Plan-E-Tech as General Manager after 30 years of fastener experience with the parent company. His background in the fastener business helped in learning what goes into producing quality tooling. Today the Ohio-based Plan-E-Tech stands as one of the largest suppliers in both USA and the world. It’s main strengths are found in excellent customer service and timely supply of what customers need.

Your Go-To Source for Standard & Customized Nail/Bolt Rolling Dies in USA Quality

“Plan-E-Tech is pretty much a specialty tooling business,” said Jim, “We produce what the customer wants in regards to thread forms and die material. We have used standard and various tool steels specified by our customers, so we are very flexible.” His rolling dies are sold to every continent on the planet except for Antarctica and in fact 75% of the customers are non-domestic. To date the company has supplied products to some of the big names such as Reed, K. Ticho, Wafios, Videx and many more.

Quality Compliance & Outperforming Craftsmanship

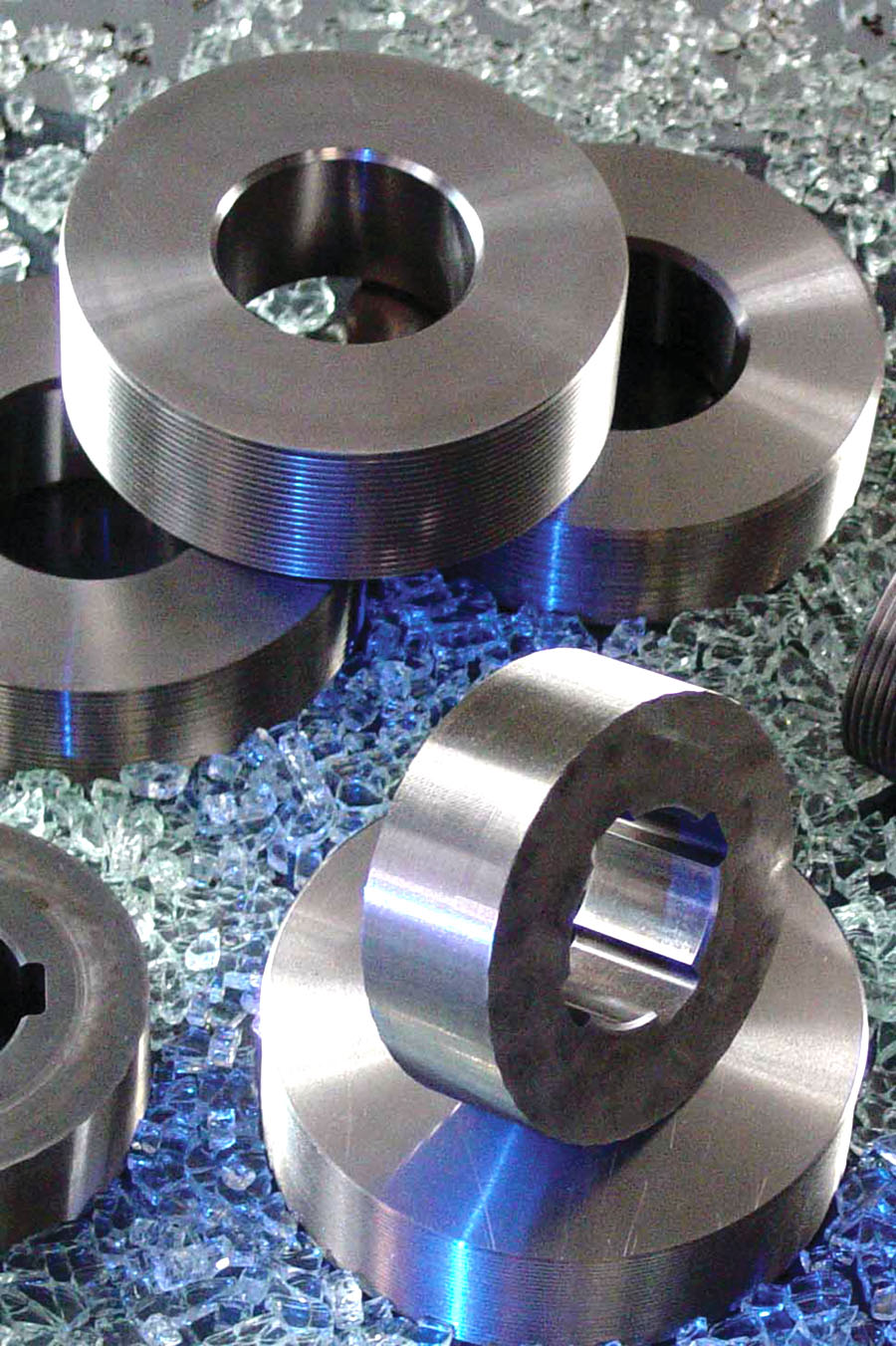

The craftsmanship of Plan-E-Tech comes from a dedication to doing the job right and concentrating on the details. As the dies progress through the shop, each operator inspects the previous person’s work before proceeding so everyone is watching. Procedures must be followed to produce the best possible product or else it won’t get out of the shop. “Our customers keep coming back to us because they know that our tooling outperforms the competition. We do a lot of the little things to make that happen such as matching sets to help with set up and increase die life,” Jim continued, “We do a very precise job on chamfering our cylindrical dies to increase bolt strength and greatly increase die life by decreasing the chipping out on the top of the die. This is a time-consuming operation but adds greatly to the quality of the dies.”

Tungsten Carbide Dies Now Available from Plan-E-Tech

About 3 years ago, Plan-E-Tech made a major investment in new machinery, tooling and fixtures. With the right equipment at hand and considerable experience, the company was able to extend product portfolio and started to provide Tungsten Carbide dies. “Tungsten Carbide is all about die life, and though the cost per die set can be up to ten times a standard tool steel set in price, customers are asking for it because in the long run they save money due to the die life and reduction in set up costs.”

Dies Reworking Service for Worldwide Clients

According to Jim, much of the business of Plan-E-Tech is in reworking worn dies. Nail dies can be reworked 2 to 4 times, and 1 time or sometimes more for cylindrical dies, but planetary dies for bolts usually cannot be reworked. The reworking process, he said, “involves stripping off the old threads, recalculating the dimensions to compensate for the loss of material and then reforming the threads as you would a new set. Reworks should preform in production as good as a new set. Set up times may be slightly longer as the smaller sizes of the dies must be adjusted for on the machine.” The reworking service is not limited to USA clients but also customers from across the world.

New Projects on the Way & Appearance at Upcoming Exhibitions

Jim said Plan-E-Tech is working on a project to produce screw shank forms in tungsten carbide dies for the nail industry. The project is on trial tests and hopefully will be available later this year. Furthermore, Jim confirmed the company will exhibit at IFME, IFE Las Vegas, STAFDA in 2019 and Wire Düsseldorf in 2020. “I hope you find your way to our booth at one of the shows and I look forward to meeting and talking with you.”

Plan-E-Tech contact: General Manager , Jim Kasper

E-mail: sales@plan-e-tech.com

Subscribe