Japanese Top-notch Fastener Counting Machines Maker Koshinsha Co., ltd.

by Dean Tseng, Fastener World

Koshinsha has turned 40 years old. It started as a factory automation machine distributor until someday it got an R&D order from a Japanese giant and started making machine controllers. Later, it gave birth to what is now widely known as “Digital Area Counters” to solve the problems of fastener clients suffering the inevitable miscount of traditional “sensor-type counters”. Furthermore, it also develops “environment improvement machines” such as dust sensors in response to carmakers request, as well as distributes coolers/heaters. It even has a foothold in the food industry, because surprisingly its Digital Area Counters are used to count food materials, frozen foods and even plant seeds besides fasteners. This proves Digital Area Counters can count many types of products with complex shapes. At this point, you must be curious what is so accurate and versatile about Digital Area Counters.

Koshinsha Core Technology: Groundbreaking Fastener Counting Algorithm

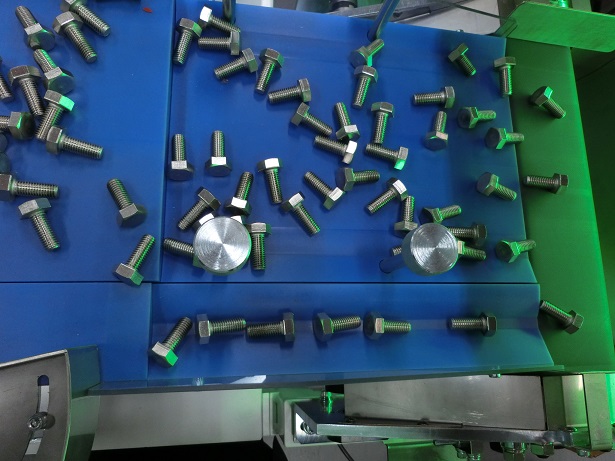

Digital Area Counter is Koshinsha’s counting system comprising an LED light source, a camera, and a digital area counter controller. The system combines the patented Algorithm, Field Programmable Gate Array (IC), and CPU to make high speed and accurate fastener counting possible. Now here’s how the system works. Your fasteners are carried by a belt conveyor or a rectilinear vibrating feeding system, the fasteners drop before the LED light source, and then the counter detects the fasteners’ silhouette and determine the number of dropped fasteners. If multiple fasteners overlap with each other during the drop, the counter will compensate for the overlap based on the fastener specifications registered as default settings, and count the right numbers. Moreover, the counter can even cancel counting metal dust or paper dust that shouldn’t be counted in the first place.

In my interview with the executive director Mr. Mitsuhide Sirakawa, he said: “Such counting technology hasn’t received attention until lately. In the past, the use of weighing scales was enough for fastener counting and shipment, but not anymore now, because domestic parts are increasingly exported to be assembled overseas, and scales cannot cope with the increased amount of export.” Additionally, the miscount caused by vibration or attached fluids is a big drawback of scales, particularly when counting lightweight precision screws or pressed parts with complex shapes. Currently, there’s another way of counting which is by a light sensor, but it has some drawbacks: (1) Slow processing speed and higher cost due to the inability to do simultaneous multiple-lane counting; (2) Low precision (Tending to miscount nuts because their hollowed centers will mislead the light sensor); (3) Sensor sensitivity must be frequently re-adjusted when trying to avoid dust, or be completely cancelled to avoid larger scraps; (4) The fasteners have to stay close to the sensor which is more likely to be contaminated by fluids. On the other hand, Koshinsha’s Digital Area Counters can count fasteners on multiple lanes simultaneously, thus becoming faster and cost saving, and the lens-protected sensor is set at a distance from the dropping fasteners so there is no concern for fluid contamination. Digital Area Counters can also be used with Koshinsha’s environment improvement machines to remove attached dust and count fasteners in a continuous production line.

New Product Development & Prospect

Koshinsha has a myriad of renowned clients including Toyota / Honda’s parts suppliers, and Nitto Seiko. The executive director noted, “Carmakers’ requests are pushing fastener makers to switch from weighing scales to counters. Although our focus is on the Japanese market, we are already supplying products to China and Thailand.” The company is developing a new sorting machine designed to visually detect incorrect products on multiple lanes of conveyors. This machine will be able to sort over 3,000 products in a minute. “The trending topic of the Japanese fastener industry now is accurate number of products and mix-up prevention. We will even roll out color camera equipped sorting machines that can sort by colors.” He added, “We are seeing increasing incoming orders and expect revenue growth while keeping an eye on the United States’ withdrawal from TPP and its re-examination on NAFTA”. Koshinsha has exhibited at FOOMA JAPAN 2017 in mid-June where visitors could find its latest development.

Contact: Mr. Mitsuhide Sirakawa, executive director

E-mail: info@koshinsha.jp

Subscribe