Industry Activities

Chinmore Industry: Customized Parts Processing & Zero Customer Complaints

Add to my favorite

2020-03-11

Iconic Figure in Precision Parts

Rooted in New Taipei City with 20 years of history, Chinmore is an iconic figure in precision parts processing. Besides providing parts used on antennae, it manufactures various types of precision parts in materials such as iron, copper, steel, stainless steel, and PTFE. The company can process parts of diameters ranging Ø1-Ø36mm, and of lengths ranging 0.5-100mm, within 0.005mm tolerance. It has clients from around the world and satisfies clients from various industries in terms of quality, service and lead time. Zero complaints, high capacity, short lead time, capability to take rush orders and high customizability are the biggest strengths of Chinmore.

Sales Rise After Moving to the New Plant

It has been a little over a year since Chinmore moved to the new plant. Fastener World went to Chinmore again and the company said in an interview that the expansion of machine tool department increases its parts processing capacity by more than 50%. “Since we expanded our plant, we have purchased new automated machine tools from Japan that have increased our daily capacity and shortened our lead time. We’ve also added new staff to the machine tool department. By inviting clients to visit us, we gain their recognition on our capabilities and their trust, thereby increasing orders and capacity. Our sales have heightened quite a lot.” With the aid of high precision equipment, Chinmore can quickly handle domestic OEM and ODM demand.

Multiple Layers of Strict Quality Check in Manufacturing Process

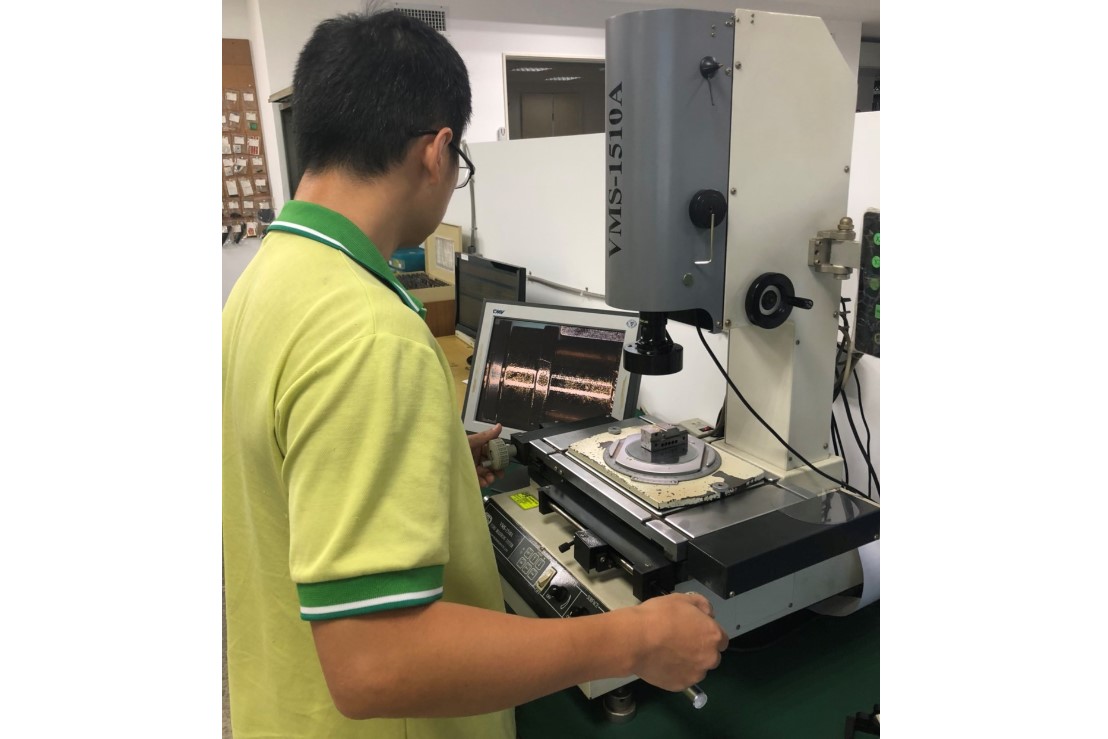

Certified to ISO 9001:2015 and ISO14001:2015, Chinmore’s precision parts go through strict standard operation procedures in every process including picking and feeding materials, processing, testing, inspection and shipment. The company adopts automated 3D projectors to perform inspection and ensure stability and consistency in each processing and finished products quality. Chinmore said clients can provide drawings, sizes and requests for special specifications for engineers and technicians to determine the feasibility of production. “Our manufacture is fully compliant to clients’ requests. Samples will be made and provided to clients for confirmation before mass-producing new products. Our quality check is monitored fully according to clients’ standards.”

Goals for 2020: Participating in Exhibitions and Gaining New Clients

This year Chinmore focuses business on market development. It develops new clients by participating in multiple exhibitions, and therefore increases orders, develops quite a few new products and increases sales.

“This year we will endeavor on increasing clients and orders. In the past we mostly attended telecommunications and computer exhibitions. This year we will evaluate on hardware or machine exhibitions.” In 2020 we will definitely see Chinmore more vibrant on the world stage!

Chinmore’s contact: Ms. Mandy Wang

Email: mandy@chinmore.com.tw

竣茂

客製精密零件加工

新廠

Chinmore Industry

customized precision parts

new plant

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Industry Activities

2020-03-30

Subscribe