Automated Industrial Machinery Inc. (AIM Inc.) Presents AccuThread Module Tailored to Wire Parts Threading

by Dean Tseng, Fastener World

AIM manufactures 2 and 3 dimensional CNC wire bending machines and accessories. Founded in 1992 by Mr. Constantine Grapsas, AIM has grown to become a premier CNC wire bending machine supplier serving customers worldwide. With many product innovations over the years, AIM has established a strong niche in the industry.

As an industrial wire bending machinery maker, AIM manufactures over 85 models of 2D & 3D CNC single or multi head benders, covering a wide range from 2 to 25mm with inline or external accessories such as welding, cold heading, chamfering, punching, drilling, threading, cold heading and marking, providing complete production automation for the automotive, agricultural, appliance, construction and medical markets. The company has customers in the North and South America, Europe, Asia, Africa, Middle East, India, Russia, Australia with the highest sales in North America.

AccuThread-

Cost Reduction & Great Coping of Complex Parts with Next-Generation Capability in Development

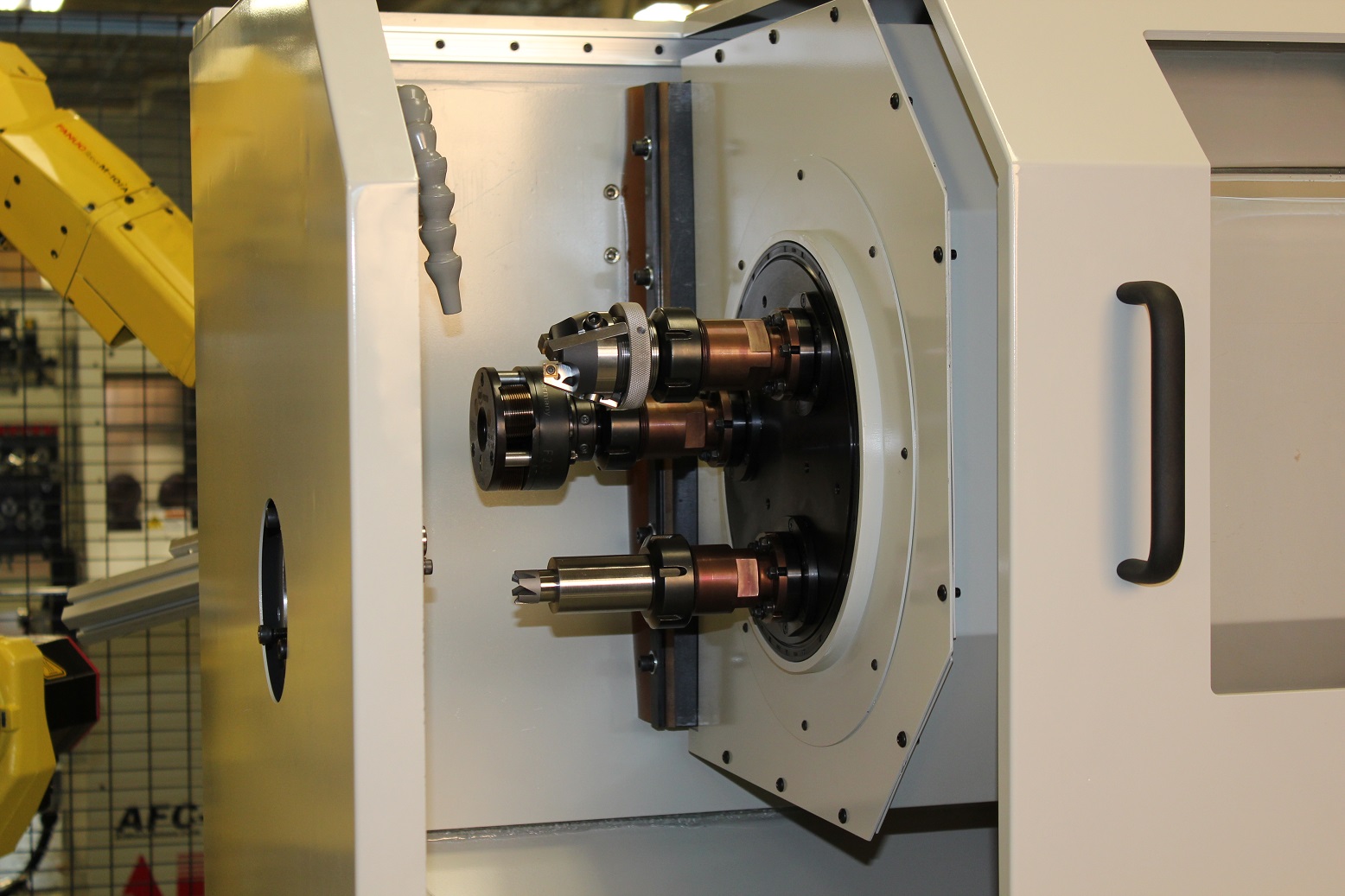

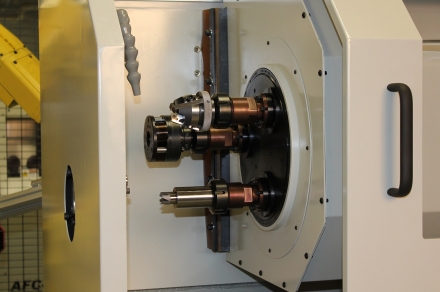

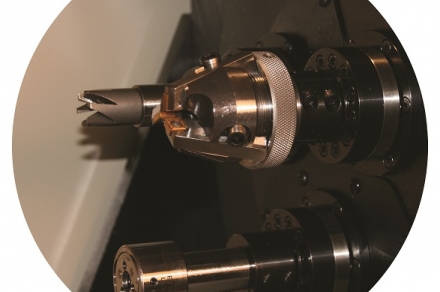

With a plethora of customer requests, AIM developed a threading Module in order to accommodate threading capability for the wire parts produced from our wire benders, called ATH series. The ATH (AccuThread) modules encompass a total servo system which includes a three position turret system, providing all operations needed for a threading operation: Turning, Chamfering and Cut or Roll Threading using standard tools available from many tool manufacturers complying with English and Metric standards. The ATH can be set in front of a wire bender or it can be part of an automation cell with a robot, reducing production costs by eliminating additional part handling operations. It increases machine capabilities to do more complex parts complete, without the need for manual secondary operations and provides greater ability to quote/bid more complex geometries, resulting in a competitive advantage.

AIM has always been working in enhancing wire operations, automating production and increasing efficiencies which result in higher profits and better quality products. The next generation of the ATH includes automatic Quality Control with 100% traceability of production failures and automatic part verification via high resolution imaging technology, mostly needed for the automotive industry.

Specialized AIM Agents Across 5 Continents

AIM has many agents worldwide in more than 30 countries. “The best route for our potential customers is to contact AIM directly with their production requirements through our website at www.AIMmachines.com. All of the requests are routed directly to our engineering team which assesses the production needs and recommends specific models depending on the requests,” said Constantine. When asked about a possibility to add more agents across the world, he noted, “There is always a need for agents but AIM only settles for “educated” agents. In order to be an AIM Agent, you would have to go through vigorous product training, usually held in Chicago, once a year, beside the trade show events.”

AIM will be exhibiting at WIRE 2018 in Dusseldorf, Germany, the Wire Expo 2018 in Nashville, TN, USA at the CASMI trade show in Chicago, the Fabtech show in Atlanta, USA and many others. Anyone interested is welcome to contact AIM or the agents in your regions.

AIM contact: Joseph Pastore, Global Sales Manager

E-mail: JosephP@AIMmachines.com

Subscribe