Heroslam- a Top Quality Supplier of Thread Rolling Tools

Focus on Main Fastener Industry Players & How They See the Middle East and Turkish Markets

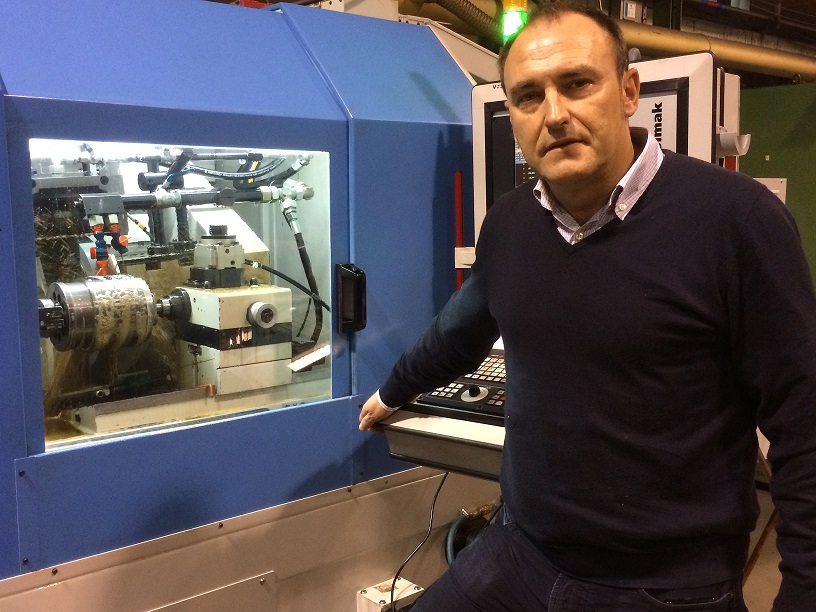

▓ Heroslam- a Top Quality Supplier of Thread Rolling Tools

The Bilbao, Spain-headquartered Heroslam is a leading manufacturer of top quality and long life thread rolling tools for the fastener industry. With nearly 70 years of experience, it is able to offer a complete range of high performance thread rolling tools including flat and planetary dies, cylindrical thread rolling dies, etc. Its products are manufactured in-house “from-beginning-to-end", including heat treatment and coatings. It exports 80% of its production, with customers in more than 35 countries.

It is a 100% employee owned company and offers customers a first-class technical support service on the design and manufacture of special tools for specific applications. Thanks to the extensive knowledge of its customers’ production requirements and to its ongoing search for excellence and technological innovation, it is proud to manufacture consistent and reliable tools with a long service life and excellent performance. Its latest innovation is GG coating which significantly increases the tool life. As a result, its customers are seeing their tool life increase in an average 30% and more.

Its thread rolling tools are mainly used by fastener producers within the automotive and aerospace industries. The longer life of its thread rolling tools is especially significant when rolling hard materials. The combination of its specially designed profiles along with the customized RRO features and the GG coating, make its tools capable of rolling a bigger quantity of parts, allowing customers improve their efficiency and reduce production costs.

Another important feature is its ability to make customized designs of combination tools that are capable of performing 2 or more operations in one single step. These combination tools allow its customers increase their production capacity and reduce their production costs significantly.

“We do not see much difference between Middle East/Turkish markets and other markets. We see a difference between customers. Customers in Turkey and in the Middle East maybe more price sensitive than customers in other markets, but in the end, if they are delivering parts to the automotive or aerospace industries, they need good quality tools in order to produce good quality products and the automotive and aerospace industries expect the same quality levels independently of the country in which the parts are produced.

“Turkey has a strong and very competitive fastener industry. As a consequence, there are several strong local producers of thread rolling dies in Turkey and tools are also imported from first class European and Asian producers. However, we take this as a challenge and as an opportunity to do better every day. We know we have our own market niche within the automotive and aerospace fastener industry and we manufacture a wide range of tools for many different thread rolling applications. So, we’re confident about capabilities and we believe we can be a strong player in the Turkish market. Turkey is an interesting market for us because of the high potential of the Turkish industry, with big players in the fastener industry that are increasing their quality level and their international presence, becoming well known and respected brands. We also have multinational customers with production plants in Turkey and we are also their tool providers there. We think Turkey is a country with a high potential for us and we want to be present in Turkey in the long term,” said Customer Care Team Manager Alberto Gabika

“In the Middle East, the volume of the potential market is not so high as in Turkey, but we have good customers that we have supported for years and we want to continue being their partners in the future, especially in Iran, where we expect a long term growth once the sanction period is overcome, as it seems to be. We have partners in Turkey and Iran and they are in permanent contact with our customers for whatever they may need. We also travel to these countries on a regular basis to address together with our customers how we can improve our thread rolling solutions for them.

Our presence at local fastener exhibitions is also a good opportunity to meet customers and to have a first-hand knowledge about the market trends. We will be present at Fastener Fair Turkey in Istanbul in March 2016 where we expect to meet our customers and show them our wide range of thread rolling solutions.

Our most important market in the Middle East is Iran and obviously the unstable political/economic situation has had a negative impact on our customers and therefore, on our sales. However, we see Iran as a stable country and a good place to do business thanks to Iranian entrepreneurs that are working hard to improve the situation of their companies. We think that Iran has not been able to develop the fastener industry to its full potential because of the difficulties they have gone through due to the sanction programs, but we are confident that this situation will change for better in the coming months/years,” added Gabika.

In Gabika’s point of view, the fastener industry is expected to grow at a good pace in the coming years as a consequence of the growth predicted in the automotive and aerospace industries. It is obvious Heroslam is highly influenced by the performance of the fastener industry. It has had positive and stable growth over the past few years and Gabika believes that it is in a good position to continue growing.

The quality standards for automotive fasteners are becoming more demanding and they are now very similar to certain aerospace fasteners. In order to obtain better quality threaded parts, OEMs are progressively requesting their fastener providers to threaded parts after heat treatment. This means better thread quality but it has a negative impact on tool life. To match this increasing demand, Heroslam is constantly investing in R&D on new tool designs, materials and coatings with the goal of producing long life tools to help customers become more competitive. On this regard, it has the advantage of having its own heat treatment and coating facilities and a long experience on these processes that have allowed Heroslam to develop its own coatings, such as the well-known GG coating, that significantly increases tool life when rolling hardened parts.

Subscribe