Industry Activities

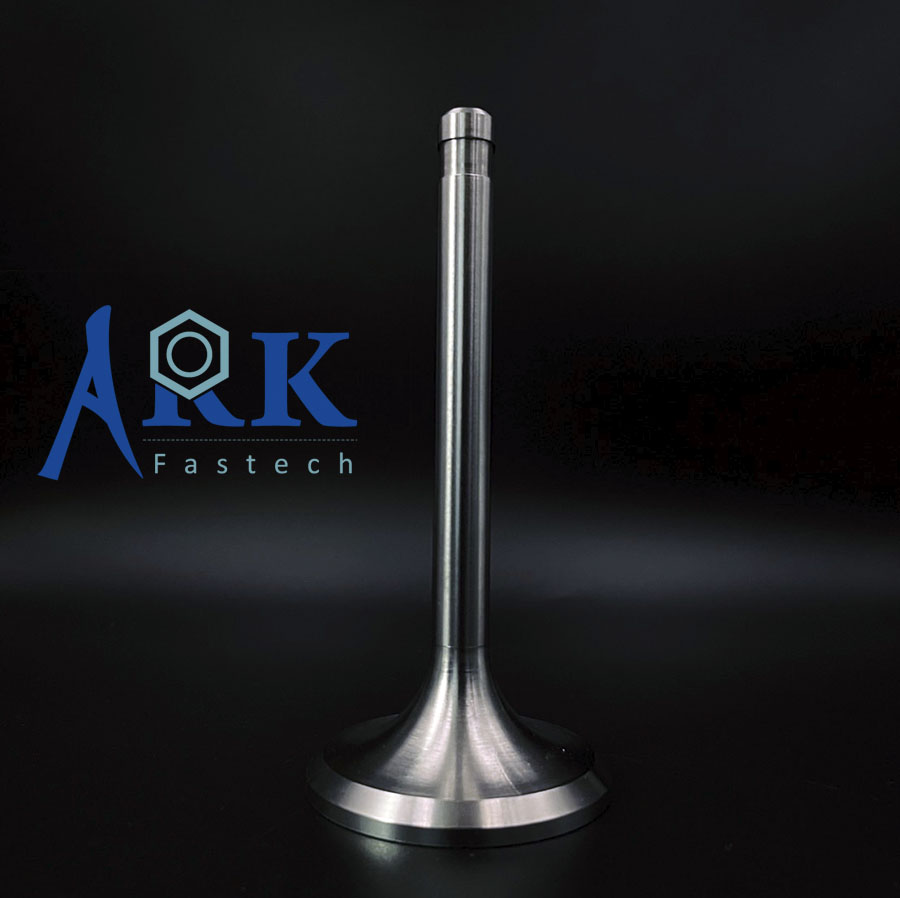

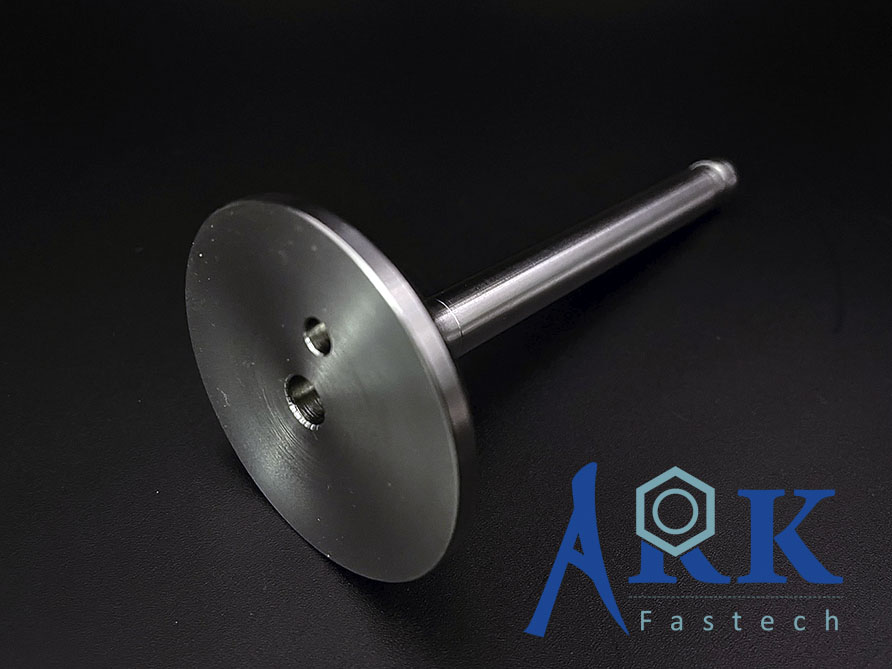

"Cobalt-based Alloy Valvetrain” by ARK Fastech

Add to my favorite

2023-01-16

The First Choice for High Strength, Corrosion Resistance and High Temperature Resistance Applications

ARK Fastech Corp. recently cooperated with an experienced associate partner to develop a product made of innovative material - cobalt-based alloy, which has strong corrosion resistance, high temperature resistance and performance strength performance. ARK Fastech is also the only fastener manufacturer in Taiwan that has successfully developed finished parts using this innovative material.

Specializing in High-end Applications to Enhance Customers' Product Competitiveness

Cobalt-based alloy valvetrains are suitable for top-level supply chain applications such as aerospace, petrochemical, energy, wind turbine and optoelectronics. Because of its high corrosion resistance (more than 30 years on average), high temperature resistance (working temp. up to 8-900 degrees Celsius) and high wear resistance, it is not easy to produce fatigue fracture and has a higher service life compared with carbon steel/stainless steel products, eliminating the trouble of frequent maintenance and repair when the products failed in the past and reducing management labor and other costs, while retaining the excellent characteristics of carbon steel hardness and stainless steel corrosion resistance.

“This is actually a product originally developed for a Swedish customer for use in the military field, and was originally produced from other materials. But after our technical team understood its strength, friction and anti-corrosion requirements, we suggested using cobalt-based alloy, which is more wear-resistant, to produce the product, and we use 100% material and processing technology from Taiwan. The hardness of cobalt-based alloy reaches HRC33-43 at room temperature, and the Average Cavitation-Erosion property is more than 15 times of general 304, which makes this material more difficult to be machined by general turning tools. However, we have successfully found a way to use various tools and drills to complete the machining process after research and discussion with our collaborators. The actual test report data also shows that our new cobalt-based alloy can last for more than 100 hours compared to the general 304 stainless steel products that reach the wear level in 7 hours. In addition, it has excellent resistance to jamming/scuffing/abrasion/erosion/impact/high heat/oxidation/corrosion, and the material itself does not deteriorate under high temperature conditions,” according to Managing Director Jerry Huang.

Complete Supply Chain Background and Strong Technical Support

Managing Director Huang, who has many years of technical background in quality control, used to be the head of quality supply chain in Asia Pacific for a major European fastener distributor, and is very familiar with the operation of the supply chain, and has strong technical support in product development, which enables ARK Fastech, which was established only 6 years ago, to quickly meet different product requirements of customers. Inheriting the experience of major European and U.S. manufacturers, ARK Fastech focuses on high-end products for automotive applications and plays the role of a relay hub for European and U.S. customers' supply chain purchases in the Asia-Pacific region, assisting customers in product development and integration to ultimately meet their expectations.

“In addition to new products, our product portfolio also includes automotive and custom products. ARK Fastech's role is not only to help customers find products, but also to provide product solutions (e.g. material/heat treatment/plating advice, mold development multiple ways of packaging or supply chain integration, etc.). One example is our recent development of fasteners for roof rails that can solve load and stress breakage problems once and for all for our customer. Not only in Taiwan, but also in Singapore we have an agent, and in China and other places, we have collaborative factories to provide supply chain management support,” said Mr. Huang.

ARK Fastech is good at communicating with customers from the technical and cultural aspects, and dealing with different product needs according to customers. With the strong supply chain and technical support in Taiwan, ARK Fastech is dedicated to playing a reliable bridge between customers and the supply chain to create a co-prosperous supply chain environment," said Mr. Huang.

ARK Fastech contact: Managing Director Jerry Huang Email: jerry.huang@arkfastener.com

方舟

鈷基合金汽門

高強度

耐蝕

抗高溫

ARK Fastech

cobalt-based alloy valvetrain

high strength

corrosion resistance

high temperature resistance

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Subscribe