Industry Activities

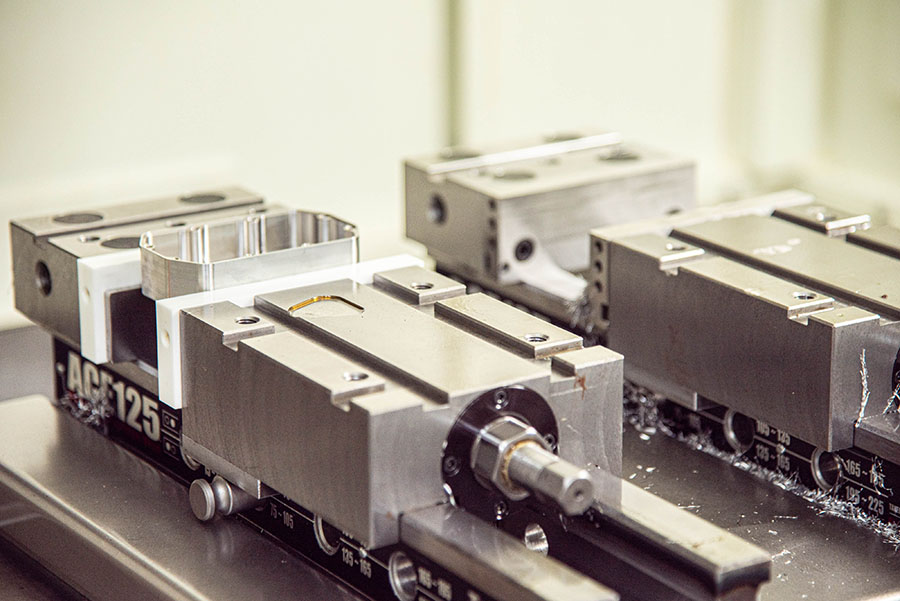

Independent Die Development Capability- YEN CHANG Shines Bright with CNC Machining Service

Add to my favorite

2021-08-18

Yen Chang Hardware Hooks & Spring Factory is specialized in production of hardware and stamped parts made of stainless steel, aluminum, and copper…etc. In recent years it has extended its footprints to the field of CNC machined parts with higher precision. Being fully compliant with the requirements of ISO 9001:2015, products of Yen Chang have been successfully applied to automotive/motorbike components, precision fixture & tooling parts for hi-tech industries, metallic fixture accessories for solar panels, electronics parts, metallic parts for biotech industries, fastener hook components, camping hardware, fishing hardware, hardware for daily use, and many other customized products.

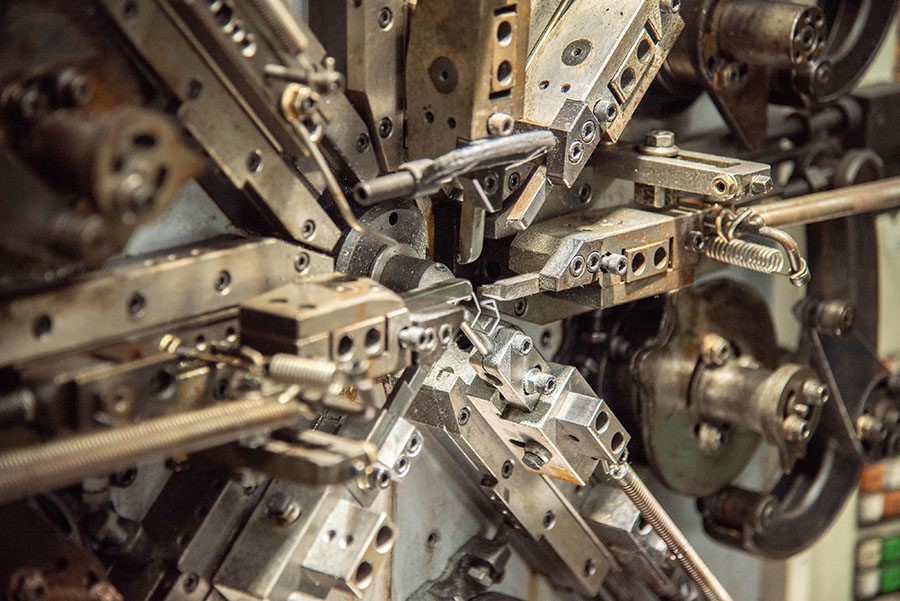

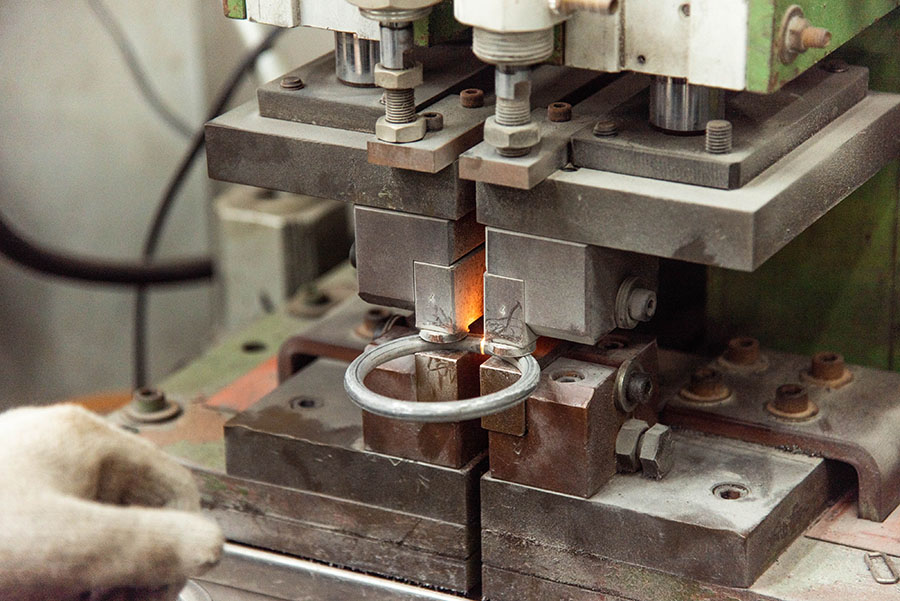

In order to satisfy customers’ demands for different volumes and adapt to the complexity of on-site machining, Yen Chang has sequentially introduced CNC spring former, multi-slide forming machine, servo press, C-frame crank press, servo bending machines, etc. For years, the high product quality, efficient CNC service, and professional team of Yen Chang have become a common view in its global customers’ minds and the best proof of its reckless efforts to help customers create their own brand value.

“Our facilities, including CNC or traditional milling machines, were mainly purchased from Japan. These facilities are of high precision, so errors can be avoided. Our professional technical team also has capabilities for independent die development and R&D in automated manufacturing procedures, which can greatly reduce the outsourced processing cost and enhance delivery efficiency. In addition, with 30-40 years of close ties with our associate factories, Yen Chang’s ultimate goal is to fulfil our social responsibility for establishing mutual growth with our factory partners and customers,” says Sales & Purchasing Manager Kiwi Cheng.

Speaking of the current situations of surging global market demand and insufficient material supply, Cheng added, “We’re always dedicated to playing a key role in reminding our customers of keeping their eyes on material price fluctuations and possible shipment delay, and offer them suitable inventory suggestions to avoid the risk of disrupted supply.”

“A good sword takes the blacksmith ten years to grind.” However, it took more than 30 years for Yen Chang to make its sword shine even brighter. Over the past 3 decades Yen Chang never stopped facility renovation and technique improvement. With the advent of more challenges, Yen Chang will not exclude any possibility of developing more products and set any limit on its service range, as it hopes to get away from the traditional framework and grow together with customers.

Contact: Kiwi Cheng, Sales & Purchasing Manager

Email: yenchang201@gmail.com

延昌五金鉤環彈簧工廠

沖壓件

CNC車修件

Yen Chang Hardware Hooks & Spring Factory

CNC machined parts

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Industry Activities

2021-08-26

Subscribe