HEBEI DUOJIA METAL PRODUCTS CO.,LTD. (HEBEI MIJIA)

About Company

HEBEI DUOJIA METAL PRODUCTS CO.,LTD. (HEBEI MIJIA)

CHINA

Yongnian District, Handan City, Hebei Province, China

+8618131004569 , +8618134004777

+8617736162821

Please login

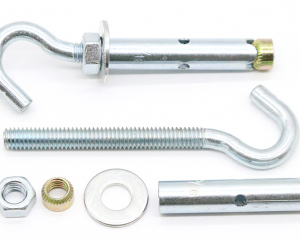

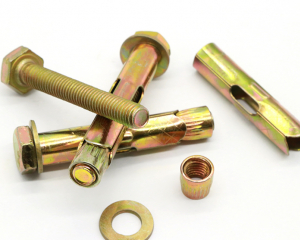

Model / Specification

M8×50, M10×60, M12×80...

Country of Origin

CHINA

Surface Treatment

Black Oxide

Material

carbon steel

Alias

Double Bolts

Patent

None

Head Marking

Capacity

100000 PCS/Month

Minimum Order Quantity

1000 PCS

Detailed Description

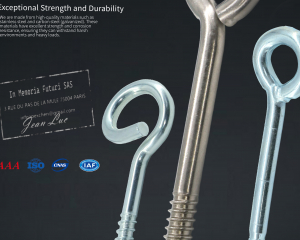

Black Double - Ended Bolts

These are black double - ended bolts, with common strength grades such as 8.8, 10.9, 12.9. Mostly made of carbon steel (with blackening treatment), they are used in scenarios like mechanical connection and equipment installation, playing a role in fastening. They belong to high - strength fasteners and can be customized with different lengths and thread specifications.

Instructions for Use:

Matching Check: Select the appropriate strength grade (e.g., 8.8, 10.9) and specification (length, thread size) according to the application scenario and load requirements.

Pre - use Inspection: Before use, check for damage, deformation, or thread abnormalities on the bolt body and threads.

Installation Requirement: When installing, cooperate with matching nuts at both ends, using tools like wrenches for fastening. Suitable for mechanical connection, equipment installation, etc.

Force Application: During installation, apply force evenly to avoid uneven stress causing bolt damage or connection loosening. Strictly prohibit over - force leading to thread damage.

Maintenance: Regularly check for rust, loosening, or thread damage in different environments. If defects affecting fastening performance are found, repair or replace the bolts promptly.

These are black double - ended bolts, with common strength grades such as 8.8, 10.9, 12.9. Mostly made of carbon steel (with blackening treatment), they are used in scenarios like mechanical connection and equipment installation, playing a role in fastening. They belong to high - strength fasteners and can be customized with different lengths and thread specifications.

Instructions for Use:

Matching Check: Select the appropriate strength grade (e.g., 8.8, 10.9) and specification (length, thread size) according to the application scenario and load requirements.

Pre - use Inspection: Before use, check for damage, deformation, or thread abnormalities on the bolt body and threads.

Installation Requirement: When installing, cooperate with matching nuts at both ends, using tools like wrenches for fastening. Suitable for mechanical connection, equipment installation, etc.

Force Application: During installation, apply force evenly to avoid uneven stress causing bolt damage or connection loosening. Strictly prohibit over - force leading to thread damage.

Maintenance: Regularly check for rust, loosening, or thread damage in different environments. If defects affecting fastening performance are found, repair or replace the bolts promptly.

Message Board