Industry Activities

New: Logistics Center + App +Hakobot. Cutting-edge Hi-tech Sunco Industries!

Add to my favorite

2025-11-21

Japan's leading fastener trading company, Sunco Industries, continues to demonstrate vitality and innovation on the world stage. Leveraging its original mascot Socket Boy and a newly constructed smart logistics center, it has been established as the most technologically advanced company in the Japanese fastener industry.

Growing Global Recognition—Socket Boy

Sunco began expanding into overseas markets 3 years ago, launching the distinctive mascot Socket Boy. Through global trade shows, magazine exposure, and diverse media (including Morinaga's Hi-Chew candy, acrylic standees, and plushies), Socket Boy's global visibility has steadily grown, becoming a beloved symbol familiar in many countries' fastener industries. The mascot's popularity has even returned to Japan, attracting significant attention at Osaka Expo 2025 and reaching more Japanese supporters. Sunco also featured Socket Boy on the new Japanese TV show "it's a screw world!" appearing alongside the Sunco president and famous comedians to promote the charm of fasteners. The 6th issue of the official “Socket Boy” magazine—a namesake of the mascot, created exclusively for Sunco and Japan's fastener industry—along with its brand new official website was launched simultaneously on October 10 to further strengthen the global fastener industry network.

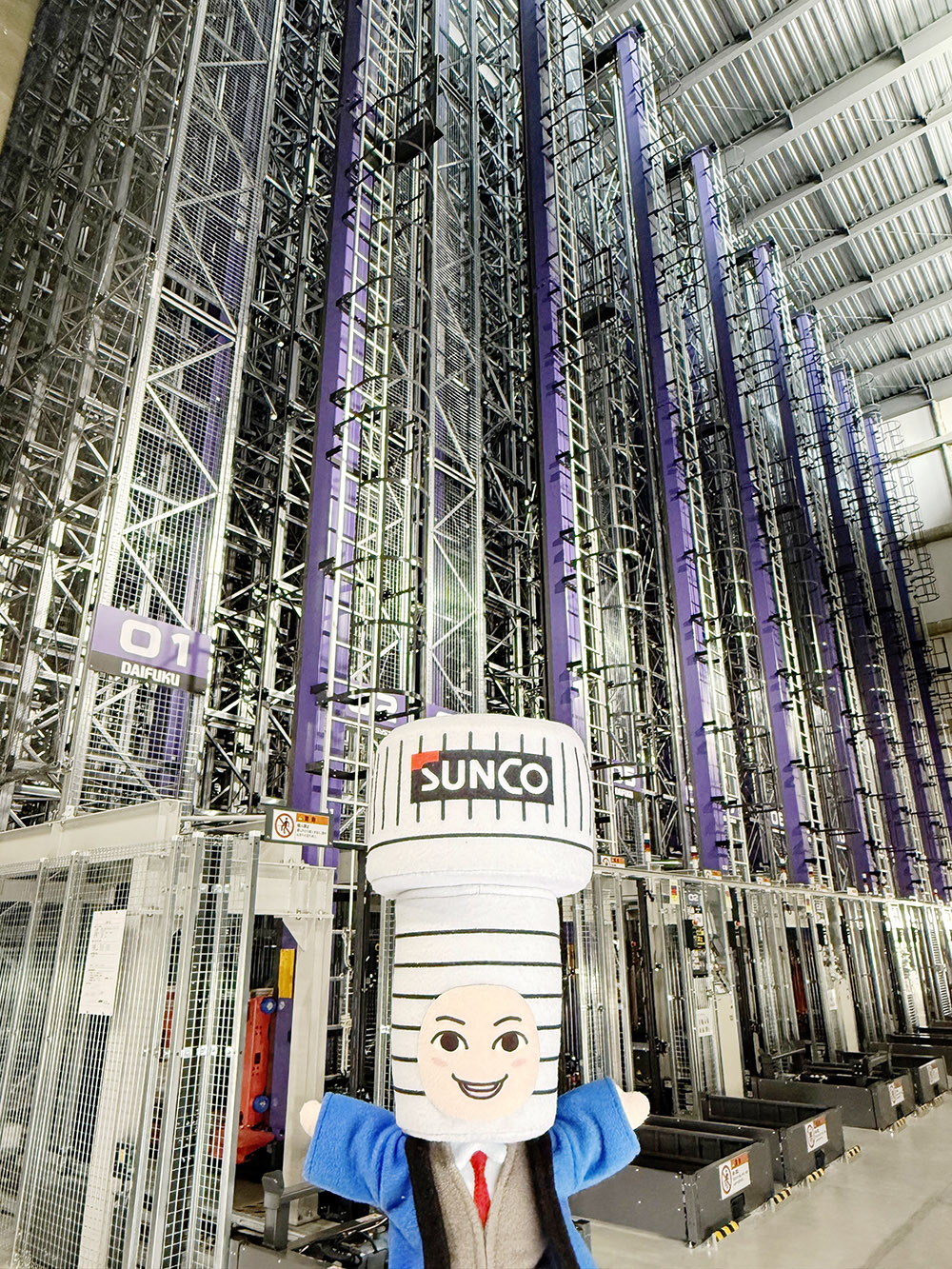

New Logistics Center Officially Opens

Since its early adoption of internet technologies, Sunco has remained at the forefront of technological innovation in the Japanese fastener industry. The newly built logistics center integrates proprietary mathematical models to optimize inventory management, shipping deadlines, and demand forecasting, ensuring top-level customer service. The facility houses 12,000 storage locations and is designed with a height exceeding 30 meters to address Japan's limited land space and high land costs. A unique scheduling system divides nearly a hundred shipping zones by carrier, effectively reducing warehouse section space and maximizing both space utilization and transport efficiency. The center also focuses on enhancing “BARA (bulk goods) service,” enabling rapid delivery even of a single piece of screw, accounting for over 60% of company orders. The company continues to expand its catalog to register up to three million types of materials and has added dedicated rotating racks, embodying a "Just in Time" philosophy to minimize unnecessary inventory and customer pain points in stock management.

Hakobot—Autonomous Delivery Robot

Sunco has achieved a remarkable breakthrough in unmanned logistics. “Hakobot” can carry up to 100 kg of fasteners, moving smoothly on outdoor roads and successfully delivering products to suppliers. Equipped with advanced sensors and AI obstacle avoidance systems, Hakobot reduces accidents and human errors, enhancing delivery safety and efficiency. Higashi Osaka is set to become a special industrial zone and future city, where Hakobot will play a key pioneering role.

3Q-Net Ordering Platform to Become an App!

Demonstrating commitment to customer convenience, the in-development 3Q-Net mobile app will incorporate a camera function that allows users to scan product barcodes to check stock, view drawings, and place orders directly—perfectly suited for users frequently on the move. Complementing the PC version, the app ensures customers enjoy a smooth ordering experience wherever they are.

Sunco Philosophy: Warmth of Tech + Humanity

Despite advanced equipment and systems, technology can sometimes feel distant. Sunco has crafted technology that balances technology with humanity, so customers not only benefit from automated smart systems but also feel warm and cared for. From the flexible 3Q-Net ordering system and thoughtful packaging designs to the flexible BARA service, the company continuously innovates with customer’s needs at the core to enhance service experience.

Setting Benchmark for 2026 Japan Fastener Industry

Entering 2026, Sunco will continue to expand its agile strategy of handling small quantities and diverse products and deepen exchanges with global fastener partners. Leveraging the influence of Socket Boy, the company will keep promoting the global recognition of Japan’s fastener industry and Higashi Osaka culture. Sunco's story is not only a corporate journey but also a model for driving industrial digital transformation and supply chain innovation.

Sunco Industries' contact: Mr. Tomokazu Takada, Assistant Manager of Purchasing Dept. of Intl. Trade

Email: export@sunco.co.jp

日本Sunco

東大阪

新物流中心

3Q-Net手機App

Hakobot無人配送機器人

Socket Boy

螺絲男孩

BARA(散裝貨)服務

扣件

Japanese Sunco

Higashi Osaka

new logistics center

3Q-Net mobile app

autonomous delivery robot

bulk goods service

fastener

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

緊固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

2026美國鳳凰城螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

德國杜塞道夫線材展

Fastener

Hand Tool

Hardware

Component

Fastener World

Wire Dusseldorf

Fastener Fair India

Fastener Fair Vietnam

Fastener Fair Mexico

Fastener Poland

Fastener Fair Italy

IFE

Fastener Fair Global

Chicago Build

READ NEXT

Industry Activities

2026-01-22

Subscribe