News

‘HNP Treatment’ Extends Cold Forging Punch Life by 1.5 Times

Add to my favorite

2025-11-20

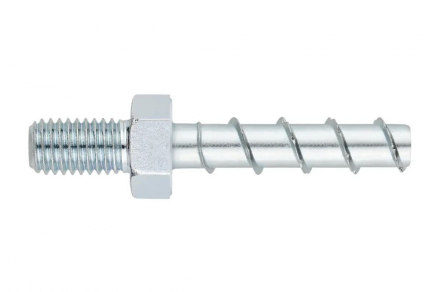

Technical challenges in cold forging and cold extrusion often involve high costs and labor from frequent punch replacements. Nisshin Partechtual (Japan), leveraging extensive die design expertise and cutting-edge femtosecond laser technology, has developed an innovative surface modification technology named ‘HNP Treatment’ (Patent No. 774560). This treatment creates countless micro-dimples approximately 50μm in diameter and 2μm deep on the punch surface, dramatically reducing friction and enhancing lubrication. The result is a significant increase in tool life by 1.5 to 2 times on average, with some tests showing up to 3 times lifespan extension. It also suppresses galling and adhesion while maintaining existing coating layers. Suitable for various punch shapes, it improves forming precision and product quality while reducing energy consumption and environmental impact. Nisshin Partechtual offers tailored processing services to help manufacturers cut costs and boost productivity.

冷間鍛造

冷間壓造

沖頭

HNP處理

Nissin Pertechtual

模具設計

飛秒雷射技術

降低摩擦係數

提升潤滑性能

延長工具壽命

cold forging

cold extrusion

HNP Treatment

die design

reduced friction coefficient

enhanced lubrication

increase in tool life

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

緊固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

2026美國鳳凰城螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

德國杜塞道夫線材展

Fastener

Hand Tool

Hardware

Component

Fastener World

Wire Dusseldorf

Fastener Fair India

Fastener Fair Vietnam

Fastener Fair Mexico

Fastener Poland

Fastener Fair Italy

IFE

Fastener Fair Global

Chicago Build