Industry Activities

Jieng Beeing- “Multi-patent Dies” Innovator Offering “One-stop Purchase”

Add to my favorite

2023-09-26

Jieng Beeing Enterprise started business with a grinding machine redesigned and repurposed for flat thread rolling dies. After moving to Yongkang Industrial Park in Tainan City (Taiwan), they expanded their product line and introduced vacuum heat treatment furnaces from France to stabilize quality. They were the first in Taiwan introducing nitriding surface treatment technology for metal dies and setting up factories overseas (Zhejiang, Guangdong, Ho Chi Minh City). They have also obtained patents for many products which are exported globally, and their turnover is still growing. This December, Jieng Beeing will be celebrating its glorious 50th anniversary, marking a new milestone in its history spanning half a century.

Sneak Peek at Their High-end Technology

They are promoting the "JP7" ultra-hard high-speed steel specially developed for 12.9 grade high-strength screws, increasing the life of dies by up to 30%! Additionally, they have developed a specialized 5-axis machine for "one-stop production of pointed-end flat thread rolling dies", completing production and processing in one machine. Besides, they purchased a German form grinder to manufacture flat dies for patented automotive calibration screws.

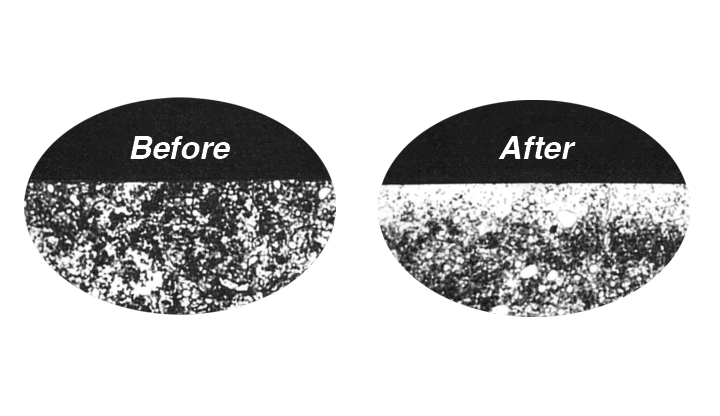

Jieng Beeing Enterprise is the first dies maker in Taiwan fastener industry to have a legal patent license for WPC technology and the right to use the WPC process, which originated from a Japanese company specialized in sandblasting/shotblasting hardening equipment. This "metal surface modification technology" uses different material types of micro-particles for different purposes, which, when mixed with compressed gas, will impact the surface of metal dies at high speeds to produce extremely fine pits, reducing the adhesion and abrasion between metals, lowering the coefficient of friction, improving surface hardness of the parts, increasing residual compression stress and the life of dies. WPC is a very environmentally friendly process, which uses consumables, production equipment and achieves results in a way different from conventional shot peening.

A European customer needed to produce a special screw with multiple horizontal threads, flanges, multiple horizontal grooves, and two vertical threads of different lengths on the same screw. By designing the customer's desired various threads onto a single flat die, the customer was saved from the hassle of using special threading machines and installing various flat dies, significantly reducing production costs. Jieng Beeing Enterprise has also instructed a domestic client to use precision form grinders instead of round dies to produce trapezoidal threaded transmission screws, which successfully reduced the cost. They have also instructed a customer to develop anti-loosening screws by replacing special engineering resin coating with a special flat die.

Next Step: Optimized Manufacturing + Overseas Subsidiaries

In recent years, they have automated the manufacturing processes to reduce human error and production costs, and they have developed materials, structures and production techniques for dies. They optimized the management of materials to ensure there is no material shortage, no overstocking, and no unused material. Since the business in China and Southeast Asia is running smoothly, they plan to set up branches in Turkey and Eastern Europe when the time is ripe. They are a dies manufacturer and trader, not only selling their own products, but also supplying fastener dies and equipment. They are looking forward to working with and becoming long-term partners with European and American fastener companies.

Contact:Susan Tung

精斌企業

JP7超硬高速鋼材料

模具

牙板

扣件

WPC製程

金屬表面改質

Jieng Beeing

JP7 ultra-hard high-speed steel

flat thread rolling dies

fastener

WPC technology

metal surface modification technology

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Industry Activities

2023-09-27

Subscribe