Industry Activities

IFE 2023 Preshow Feature- A-Stainless International Double Spiral, Square Thread, Triple Thread Screws

Add to my favorite

2023-07-18

Booth No. 663

A-Stainless in partnership with their factory Fastex Industry Co., Ltd in the last 23 years has introduced a series of innovative screw products to the fasteners market. They first introduced the Square Thread Screws that feature very low driving torque for hard wood, metal, plastic and concrete applications. This type of thread form back in 2000 was a very new concept, the very first of its kind in the market place that soon fetched market footholds in North America, Europe, Australia and Japan.

The square thread they have learned over the years besides being good for hard wood is best suited for metal applications. In the case of aluminum window frames, the driving torque reduction is well above 50 % which is significant enough to do away with head breaking problems when Austenitic, i.e., 304, 305 , 316 (A2 or A4) tapping screws are used for aluminum windows.

Two years after the Square Thread Screws, they introduced the Double Spiral Screws, also meant for hard wood applications, again featuring a general 30-40 % drive-in torque reduction verses the regular Type 17 thread cutting screws. In the same year they came up with the Triple Thread Composite Decking Screws, a much improved version over what was available in the market then. Their version has a small trim head with triple threads, i.e.., 3 portion threads of left, right and left thread design. The trimmed small head ensures that the screw head sits flush against the surface of the composite decking while the triple threads compress the plastic spiral waste materials from emerging, i.e., kept under the decking. Built on the square, double spiral and triple thread styles, they have used these variables to come up with various screw versions to suit the specific needs and requirements of their customers.

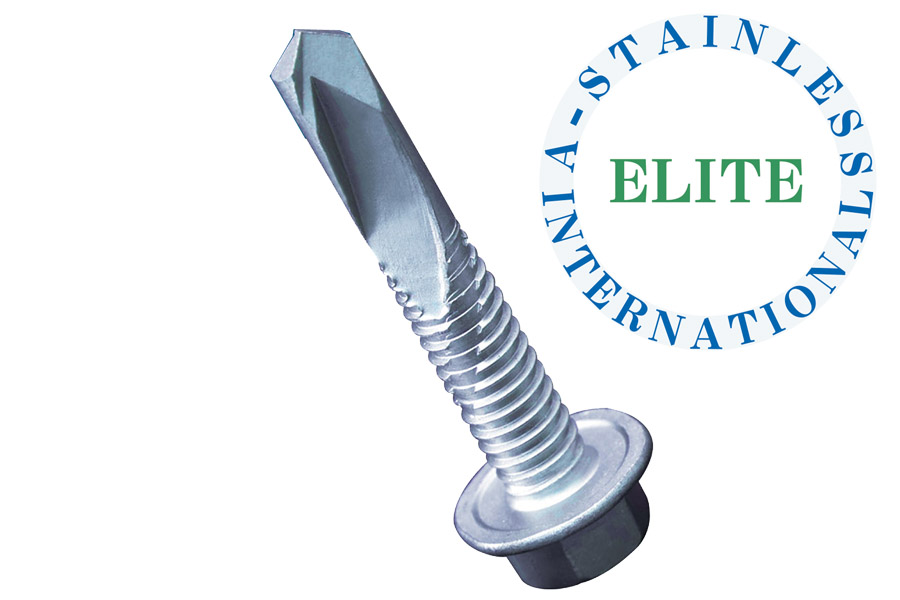

In the last three years, they have had the latest product, namely the Milled Point Self Drilling Screws made with milling machines deigned and made by their team. They have chosen to make the 6–cut milled point instead of the regular forged point for reasons of the very neat, sharp and consistent cutting blades. The milled point is preferred due to its stability and consistency while drilling thicker metal sheets that require No. 4 or No. 5 drill points.

A-Stainless is committed to making special screw parts for a wide spectrum of different applications where special attention pertaining to thread designs, work hardening, heat treatment, plating and coating needs to be taken. They welcome inquiries especially those that call for specific performing features.

Contact: General Manager Asser Liu

Email: astainless@hibox.hinet.net

A-Stainless International

Double Spiral

Square Thread

Triple Thread Screws

low driving torque

hard wood

metal

plastic

concrete applications

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Industry Activities

2023-07-18

Subscribe