Industry Activities

Eurotec- Efficient connection solutions for timber construction

Add to my favorite

2023-07-18

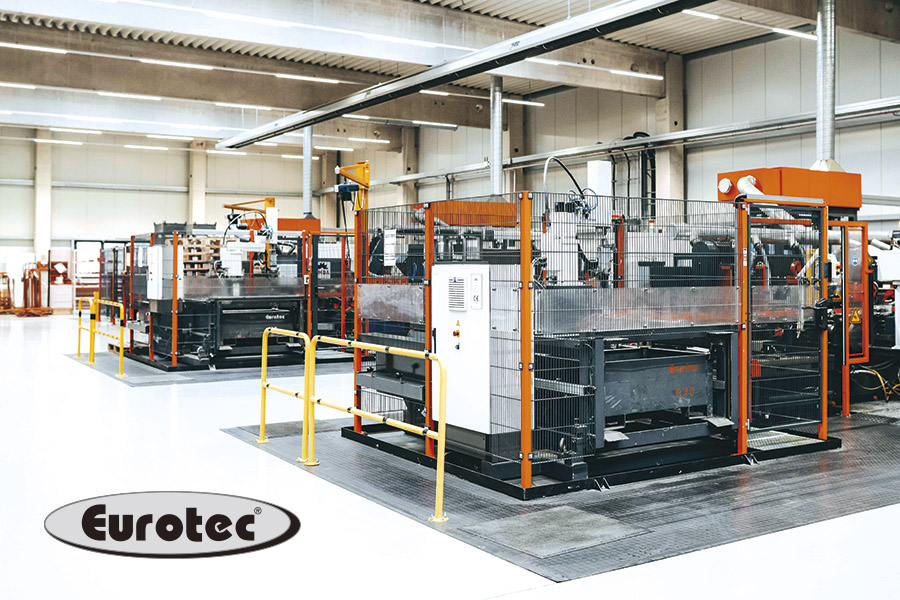

Eurotec GmbH is an established company that specializes in fastening technology for demanding construction projects in timber as well as in deck and garden construction and has been contributing to quality and innovation for more than 20 years. Since 2013, Eurotec has been producing a selected part of the wood construction screws in its own production facility in Hagen, Germany. In 2022, the company decided to expand the production area in order to create more space and set future-oriented goals–including becoming independent of the world market as a local manufacturer and supplying innovative high-performance connectors for sustainable prefabricated timber construction and timber construction in general. The production hall was enlarged to around 7000 m² and investments were made in the machine park. As a result, the company can react quickly and flexibly to increasing market requirements and increase production capacity accordingly. Equally, local production holds great potential to effectively reduce CO2 emissions in freight transport and bulk transport from alternative procurement sources.

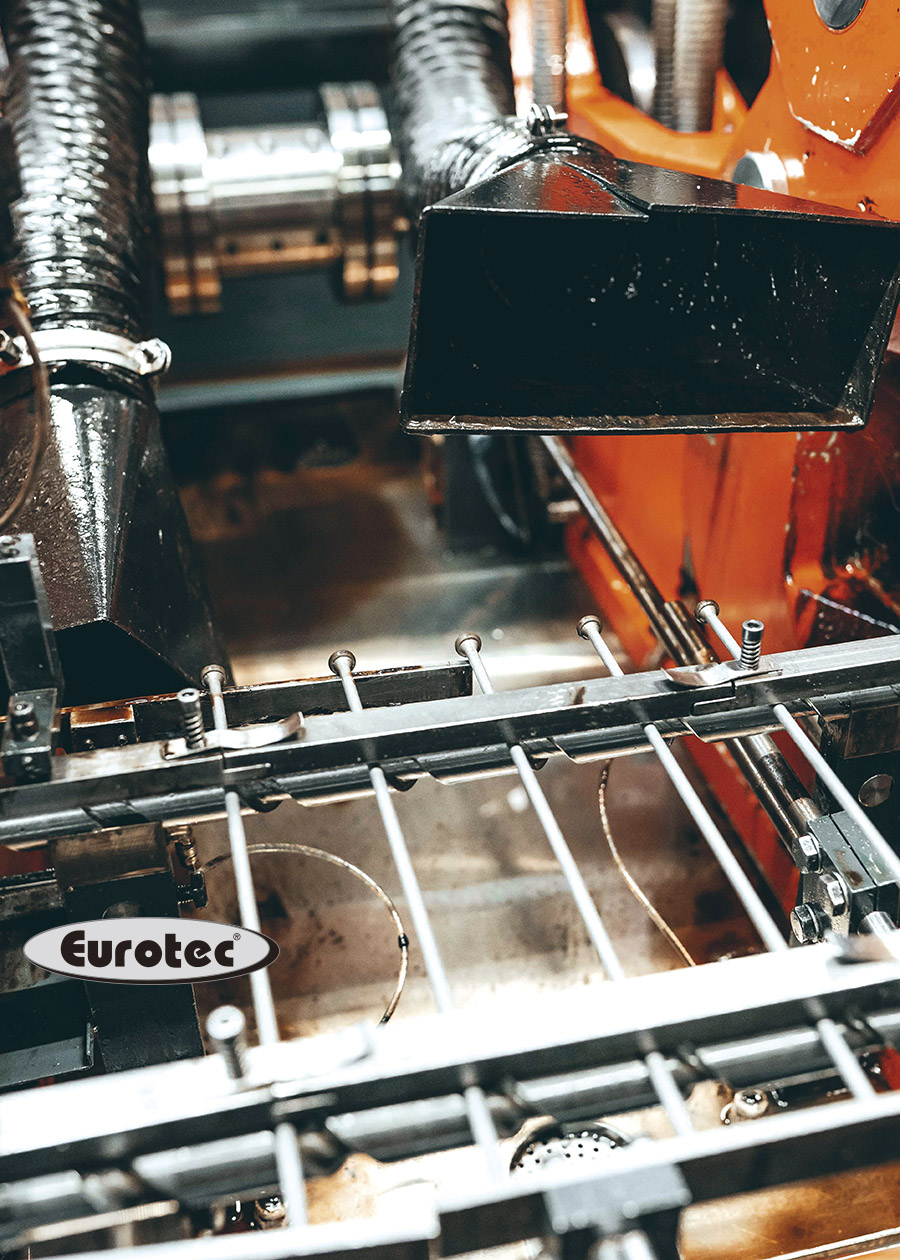

An ever-increasing proportion of wood construction screws is currently produced and will continue to be primarily produced in the future. The manufacturing processes for wood construction screws range from thread forming to head and tip geometry to screw length. The wide range includes in-house produced screws from 5 x 40 mm to 13 x 1400 mm. The production of full-thread screws reflects Eurotec's greatest production strength. This know-how forms the basis for further entrepreneurial development. In addition, the company also covers the areas of injection molding technology, stamping and bending technology and aluminium extrusion technology.

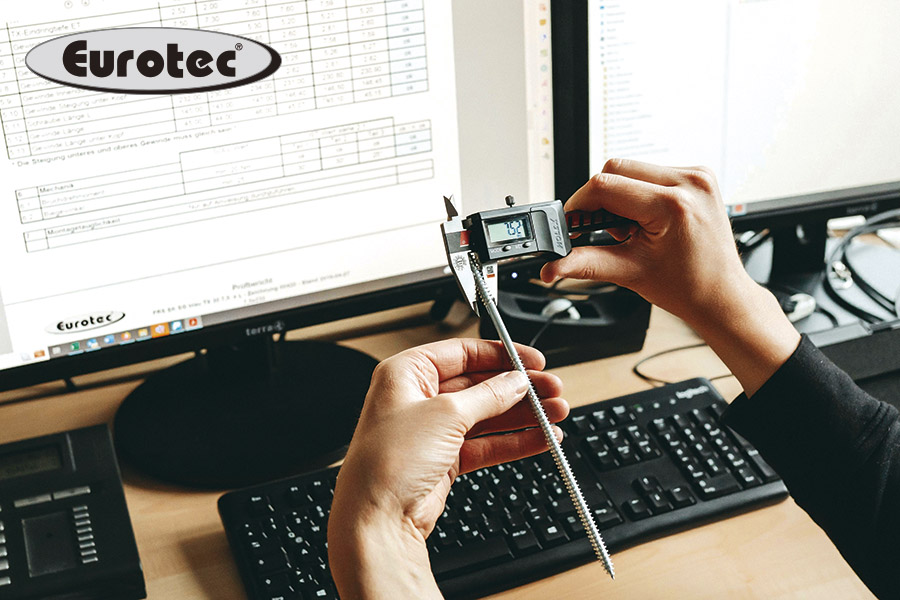

Quality Assurance at Eurotec

By subjecting to regular test procedures and monitoring of production steps according to the high quality requirements according to DIN EN ISO 9001, customers can be assured of reliable and durable products. As part of internal quality assurance, the batches produced daily are strictly checked for standards such as conformity to drawings, functionality, appearance and compliance with customer-specific specifications. Eurotec's ultimate goal is to provide customers with professional products and services and to ensure 100% on-time delivery. A large part of the fasteners in the range, especially in the wood, façade and concrete segments, have an ETA and CE certification and are suitable for load-bearing functions in various construction projects.

Sustainability in Manufacturing

The goal of all company processes is a climate and environmentally-friendly way of working: One focus is put on the sustainable production concept. For example, eco-friendly raw materials and auxiliary materials are used for production processes, energy is generated by solar systems and energy consumption is minimized by the use of LED lamps throughout the hall. Green steel is used in cold forming, which can lead to savings of up to 1.5 tons of CO2 per ton of steel.

What’s Next?

Eurotec GmbH continues to strive for the development of innovative high-performance fasteners to outperform simple wood construction screws. Climate-friendly building with wood remains an important topic, as wood offers a clear advantage in terms of CO2 reduction compared to cement and concrete. This can be clearly seen in the ever-increasing demand for professional fasteners in order to accomplish large-scale projects. Eurotec works continuously on the development of reliable and innovative fastening technology to meet these requirements.

Email: info@eurotec.team

Eurotec

connection solutions

timber construction

manufacturer

Germany

fastening technology

緊固方案

木建築

製造商

德國

緊固技術

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD