Industry Activities

“Sustainability & Safety”- Hu Pao Sets a New ESG Benchmark for Industries

Add to my favorite

2022-07-19

Investing NT$ 0.6 bn in establishing its new Guiren plant last year, Hu Pao Industries Co., Ltd., responding to the sustainability issue discussed in global industries having gradually incorporated the ESG idea into the indicators for evaluating corporate performance, spearheaded its industry peers to optimize internal management and introduce external resources within the ESG framework in order to consolidate a solid base for creating a “sustainable & safety-first”company.

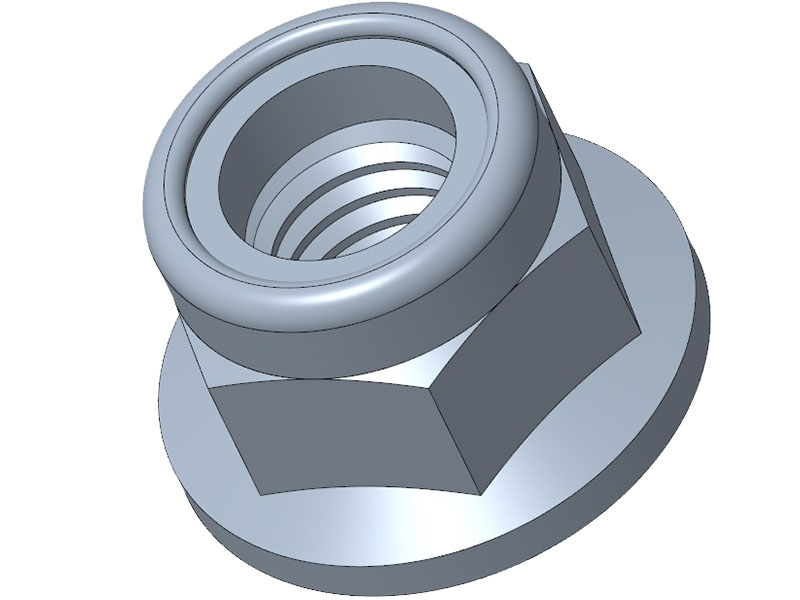

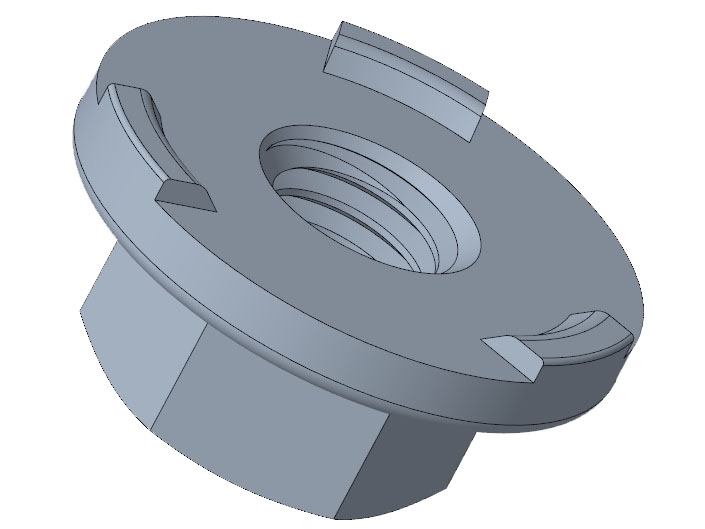

Having specialized in automotive, special, and anti-loosening customized nuts for years, Hu Pao mainly supplies products significantly used in areas with serious work safety concern. Moreover, noticing people’s stereotype of “traditional industries’ manufacturing used to cause great impact on the environment” and being a company actively seeking sustainability, Hu Pao under the leadership of Vice President Bill Wang realizes its social responsibilities, value, and outlooks, and continues to do what others haven’t done before to create opportunities for Hu Pao to earn more customers’ recognition.

Member of the 1st Session of “Zero+ College” and “Net Zero Alliance”

Cross-Industry Resources Sharing to Maximize Strength of Teamwork

“ESG is a trend and key point future regulations and customers will definitely keep a close watch on. Hu Pao pulls well ahead of more than 1,800 Taiwanese fastener companies in anticipation of bringing better prospects and future for stakeholders, employees, society, and the Earth in addition to seeking profit and added value,’ said Vice President Wang.

As a result, Hu Pao attended the 1st session of “Zero+ College”to learn with other new generation from 13 different Taiwanese industries, receive guidance from industry mentors, and make the most of resources/experience of TDEA to find a transition way toward net zero carbon emission. Over the past 6 months, Hu Pao has been receiving the guidance from its industry mentors to direct a right path for carbon neutrality, carbon emission reduction, and solutions in the next 3-5 years. On the other hand, Hu Pao is also the 1st batch of companies receiving the guidance from CJCU’s “Net Zero Alliance” aiming at integrating resources in Southern Taiwan and near CJCU to “fight as a team” and fulfils the ISO 50001 (energy management system), ISO 14064-1 (greenhouse gases emissions), and ISO 14067 (carbon footprint of products) for developing the path for net zero.

“Incorporating ESG into both publicly traded companies and SMEs is essential. Through participation in “Zero+ College” and “Net Zero Alliance” (both provide substantial guidance), Hu Pao is heading toward the compliance with ISO 50001, ISO 14064-1, and ISO 14067, i.e., starting from energy management to control greenhouse gases emissions and reduce carbon footprints to achieve the goal of net zero in the end. The Alliance is currently guiding Hu Pao to apply for ISO 50001 and prepare required documents for ISO 14064-1 auditing, which are for making Hu Pao achieve net zero quicker with the assistance of professional industry mentors. The fastener industry is closely connected with the steel industry after all. If it can develop with overall plans, it’ll be not only favorable to environmental protection and corporate sustainability, but also give customers more confidence in Hu Pao,” noted Alvin H.M. Chen, Director of CJCU Alumni Services & Resource Development Center and Associate Professor of Bachelor Degree Program in Management.

“It takes at least a year to prepare documents for some certificates. We expect to submit our application for ISO14064-1 next year and get the approval in the same year. As a result, when EU’s CBAM officially takes effect after 2026 and if our products are subject to taxes, the invisible cost is estimated to increase by 20-30%, but we’ll be ready by then,” said Hu Pao Vice President Bill Wang.

Optimized Facilities, Manufacturing, and Employment

Fulfilling Carbon Reduction via Multiple Approaches

Hu Pao focuses on its facilities, manufacturing, and employment in order to achieve carbon reduction. In terms of facilities, it set up an over 16,500 sqm, well-equipped, neatly arranged, bright & ventilated, and solar panels covered energy-saving new plant; in terms of manufacturing, it uses recycled oil, maintains good PM 2.5 levels in the plant area and goes paperless at work; in terms of employment, it also invited retirees back to share their experience, values the workplace, and offers employees bonus and free veggie meals, in order to make all employees understand how to love our Earth and protect the environment and work together to execute the Climate Change Actions.

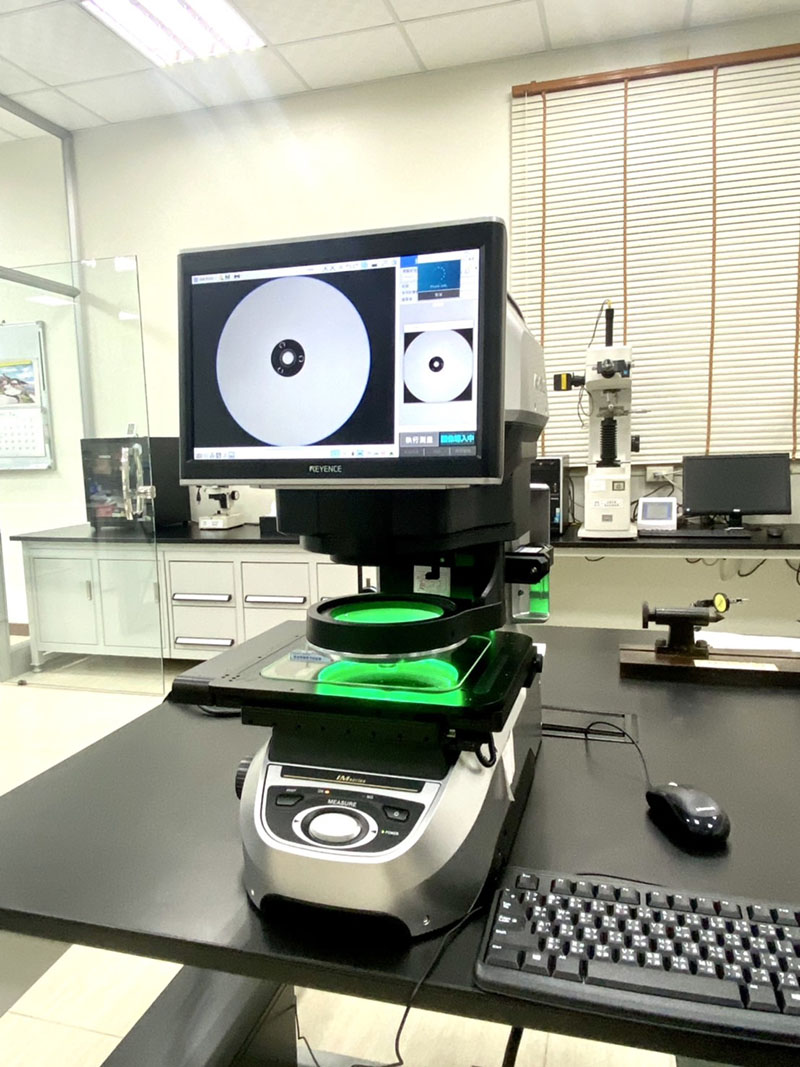

Hu Pao also plans to introduce digital IoT system into manufacturing, which is expected to finish installation and tests by this Aug. or Sep. For example, the “Measurement Systems Analysis (MSA)”for self-check and errors alert will transmit real-time data to ERP and utilizes Big Data to do statistical process control (SPC). If errors occur, machines will be stopped immediately and send notifications to QC to determine if production should be restarted or not. The Situation Room for PLC machine stoppage and online task assignment can reveal the real-time production status. In the future, it also plans to introduce PLC die service life reporting and electronic weighing blue tooth transmitting mechanisms. In the product development phase, its planning, manufacturing developing/verification/confirmation, and appraisals & corrections are also carried out in the APQP framework; in the early development phase it uses FMEA to evaluate and distinguish risks; before trial production it uses MSA to control systematic stability; in the mass production phase it uses SPC to do risk monitoring and avoid errors; finally it delivers samples based on customers’ PPAP requirements and complete confirmation and verification of developed products.

What’s worth mentioning is that Hu Pao has recently purchased Japanese Keyence 3D Optical Profilometer (VR-6000 series) and Instant Measurement System (IM-8000 series) for NT$ 5.5 million in order to ensure the compliance of each die & punch with set dimensions and avoid production of defective products due to man-made errors, which can not only greatly shorten measuring time, but also help develop more high-quality products.

“Not many SMEs will do so, but Hu Pao introduced lots of systems and equipment to ensure the yield rates of products, reduce man-made errors, optimize labor utilization, reduce futile carbon emissions, and gain more customer satisfaction and trust,” added Director Chen.

Targeting German Market with a Fresh Look of Hu Pao

Hu Pao has been doing digitalization, zero carbon transition, and structural revitalization for 3 years. However, due to the pandemic, foreign customers are unable to visit Taiwan to witness Hu Pao’s effort in these aspects. Accordingly, Hu Pao has also received “Subsidies for Industries to Develop Int’l Markets” from Bureau of Foreign Trade (MOEA). Through the new website construction and the English/German VR video, foreign customers can virtually visit Hu Pao’s new and clean plant with standardized die management and its effort invested in ESG and equipment optimization.

Vice President Wang added, “Every day we must continuously renew ourselves and be active in innovation. Don’t be satisfied until you achieve perfection. In addition to profit, a company must also create a better environment. Carbon reduction is important, but should be done with everyone’s power. With the core spirit of ESG, we can utilize external resources to increase our strength.”

Hu Pao contact: Ricky Wang (Sales Manager)

Email: hupao@hupao.com.tw

sustainability

safety

Hu Pao

nut

永續發展

安全

如保

螺帽

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Industry Activities

2022-07-19

Subscribe