News

Internally Threaded Studs & Full-inspection Device by Fuji Seira (Japan)

Add to my favorite

2021-09-08

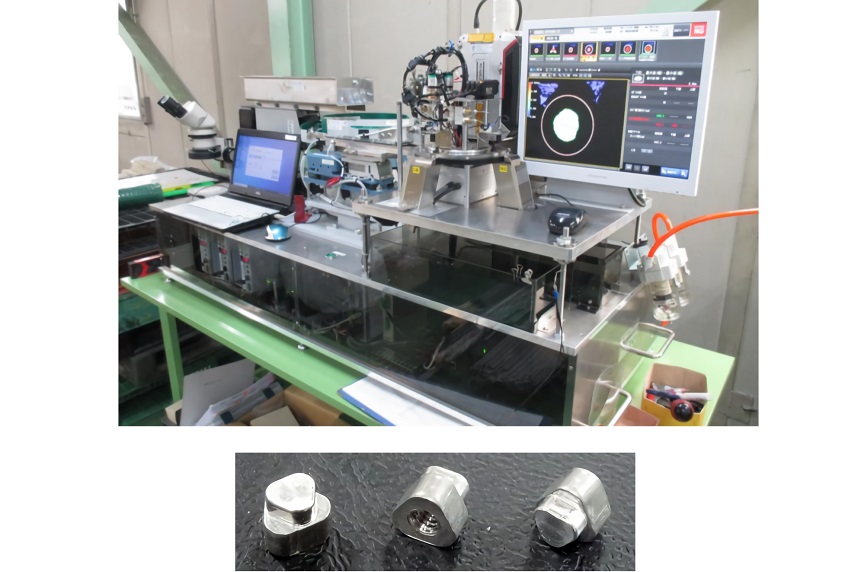

Fuji Seira successfully developed and started using a full inspection device on the "Internally Threaded Studs" used on notebooks' integrated circuits. It uses laser inspection to detect burrs and unprocessed parts, and works at a speed of 35 pieces per minute, which translates to about 5 times the speed of visual check. It makes for unmanned operation in nighttime and helps progress towards zero product defection.

The development cost JPY 7.5 million. Using laser sensors made by Keyence, the device can detect burrs that are 0.7mm long. "Internally Threaded Stud" is a product developed by Fuji Seira in response to the request for lightweighting. 72% lighter than the company's previous products, "Internally Threaded Stud" drops its cylindrical shape and changes to a triangular prismatic appearance to reduce volume, and is made of aluminum alloy instead of brass to restrain the creation of burrs from processing.

日本富士Seira

內螺紋螺柱自動全檢

Internally Threaded Studs & Full-inspection Device

Fuji Seira (Japan)

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Subscribe