Industry Activities

Higher Precision and Longer Durability- Customized Punches & Dies by Infinix

Add to my favorite

2020-03-20

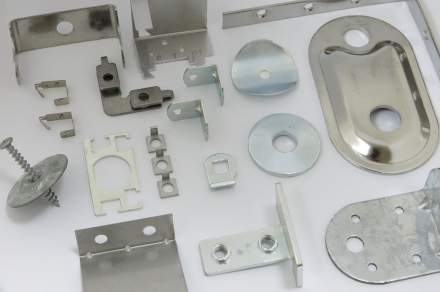

Infinix Precision Corp. provides a diverse range of customized punches and dies as its main service. According to Infinix, customization is not a big challenge but a routine work to all of its employees. As it has capabilities to offer customers punches and dies for manufacturing screws and nuts at a time, customers can purchase all products they need from Infinix without contacting other suppliers, which not only saves time, but also makes it easier for them to control lead time.

Advanced Manufacturing Equipment to Ensure Higher Precision

Since its early development stage, Infinix has begun to introduce automated machines from abroad and focus on the development of high-quality customizing service. As a result, since its inception, its products have been successfully adopted by several aerospace fastener manufacturers in Europe and America.

Infinix adopted equipment from Japan, featuring automation, high precision and better processing efficiency. With automation and programmable systems, Infinix processes its punches and dies to a consistent high-quality level without worrying about inconsistent quality due to the difference of processors. The higher strength of a machine, the higher precision of products. “Just like we can produce products with a tolerance below 0.01 mm, we can even produce punches with a tolerance below 0.005 mm as we have our self-developed machines,” said Infinix.

Segmented Dies Made from Carbide Feature Longer Durability

Having 4-/5-axis CNC processing machines, EDM, and wire cutting machines, Infinix mainly produces carbide dies for screws and nuts . “Amongst these products, our segmented dies show one of our advantages (i.e., offering longer service life). Other than that, we also produce steel and carbide punches. With our self-developed grinding machine, we can process the heat treated hardened materials directly and have the production completed in one manufacturing procedure, which can significantly lower the cost and make prices more competitive,” said Infinix.

To Improve Work Efficiency and Reinforce Market Expansion in Taiwan

“So far we’ve not only introduced ERP into our production lines, but also introduced the system to our management, which is an idea of vertical integration,” said Infinix. Moreover, as the system, which combines ERP with MES, was developed by Infinix, Infinix can get real-time info exchange via Big Data and effectively enhance the work efficiency of employees and manufacturing efficiency of its plant.

Although Infinix reported a slight drop in its order intake from Europe and America, due to the influence brought by U.S.-China trade war in 2019, it was still active in soliciting different customers in the Asian market, thus enabling it to keep fair revenue in 2019 and stay away from turmoil in the global market. In 2020, in addition to keeping continuous growth in overseas sales, Infinix also hopes to strengthen its sales in Taiwan (a reputed fastener manufacturing heartland in the world) and make an effort to achieve a remarkable result.

Contact: Ms. Nini Ni (sales representative)

Email: tooling@infinix.com.tw

英飛凌

客製化模具沖棒

高精度

一站購足

Infinix

customized molds and dies

high precision

one-stop shop

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Subscribe