The Best Self-drilling Screw Formers Supplier- Pointmaster Machinery Co., Ltd.

Dedicated to the field of self-drilling screws for more than two decades, Pointmaster Machinery Co., Ltd. was initially started with only one machine model available for supply. However, as it continues to develop products with customers, listen to their demand and roll out new products, it has nowadays become a specialized self-drilling screw former manufacturer offering the most complete range of models.

Pointmaster was founded in Nov. 1998 and has been just celebrating its 20th anniversary this year. On Jan. 8th 2019 it even reached a milestone for hitting 1,000 sets of self-drilling machines sales. Recalling the time when Pointmaster was just established, General Manager Chi Wei Liao said, “Although it was once rumored that we would soon end the business, and following after that, we had dispute with shareholders, encountered the risk of our plant being auctioned and a 3-year long lawsuit forcing us to be summoned to court for times in Taichung, fortunately, we finally won the case and successfully survived the difficult time.” The delivery of the 1,000th set of machine was indeed a new milestone for Pointmaster and providing high quality service will be always the tenet for Pointmaster in its next 10 years.

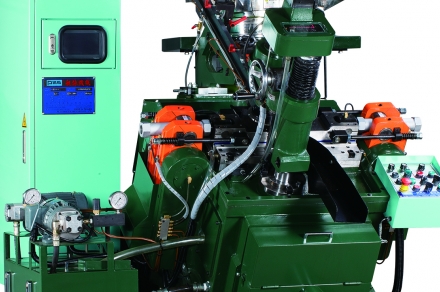

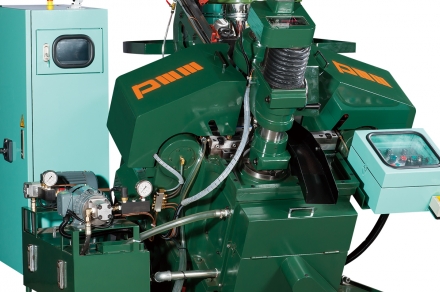

Various Specifications with Durable & Robust Body Design

The self-drilling screw former is used for producing self-drilling screws only, so the demand for this machine is basically lower than that of other fastener machines. Such a situation, however, does not discourage the passion of Pointmaster for manufacturing self-drilling screw formers. Instead, it aroused its interest in the R&D. As soon as customers file their complaints, Pointmaster will immediately have the products tested and modified to the best condition, no matter how long it will take to solve the problem.

The self-drilling screw formers of Pointmaster can be divided into two structures: one-stroke and two-stroke, and they can be further divided into different types according to sizes of screws for which they are designed to manufacture. The two-stroke structure is designed for manufacturing stainless steel screws, while the one-stroke is designed for manufacturing carbon steel screws. PM-100, PM-100S, PM-200 and PM-210S are all popular models on the market. The manufacturing speed of these models can be up to 600 pcs per minute. In addition to standard models, the special model PM-W250S can be also supplied as per customer’s request. The currently largest model of Pointmaster is able to produce self-drilling screws in the length of 600mm. Pointmaster has also developed a product with many patents, which are made from different cast irons to offer higher rigidity and stronger structure that is 1.25 times the tonnage of other counterparts.

The patented “Dual-Clutch Control System” adopted by Pointmaster can prevent the machine from being affected by inertia and allow it to make a sudden stop in high-speed operation, thus eliminating the quality issue caused by feeding obstruction or die collision and protecting dies and increasing manufacturing efficiency. This is why so many Chinese manufacturers prefer importing their formers through Pointmaster to buying cheaper locally made machines. All machine models of Pointmaster are CE certified and their quality is also recognized in the EU countries.

Highly Efficient Repair Service & Expanding Business Reach to Emerging Countries in the Future

When it comes to aftersales service, Pointmaster is definitely second to none. For example, in order to efficiently and immediately solve customers’ problems, Pointmaster set up its repair & service operation right in the fastener manufacturing hub- Gangshan (Kaohsiung), saving much time for its repair staff who used to travelling far to fix customers’ problems. It has also associate partners in Guanzhou and Zhejiang offering aftersales service to its Chinese customers. Pointmaster never stops training its own repair staff, and if customers have any problems that they are unable to deal with, Pointmaster can also send its men there to offer real-time technical support.

Current sales of Pointmaster are mostly in overseas markets. The significantly increasing demand in the emerging countries (particularly Vietnam, Indonesia and India) in recent years due to more matured manufacturing conditions has also benefited the order intake of Pointmaster. Considering the establishment of Formosa Ha Tinh Steel Corporation, which later resulted in an investment boom, Pointmaster is also planning to set up a service operation in Ho Chih Ming City. Currently Pointmaster has no exclusive agent and all interested companies are welcomed to contact Pointmaster for further collaboration.

Contact: Chi Wei Liao

EMAIL:tforever@ms29.hinet.net

www.fastener-world.com.tw/pointm

Subscribe