Precision Metal Processing & Hardware Manufacturing Expert -- Chinmore Industry Inaugurates a New Factory with Expanded Capacity

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

Flipping through the 20-year business history of Chinmore Industry Co., Ltd., the company did face lots of challenges, but went on steadily. Its significant growth year after year also impressed the industry. Since its inception in 1997, Chinmore has been dedicated to automated CNC lathe machining, various electronic parts/plug parts/hardware accessories, mold design & processing and has won industry-wide recognition. This year (2018) its new factory has been also put into operation, making the scale and capacity of Chinmore reach a higher level and service provided to global customers more complete.

Additional Capacity Increases Customers’ Confidence in Chinmore’s Quality

Chinmore’s customers come from around the world, so how to satisfy customers from different industries in terms of quality, service and lead times is really important. The point worth mentioning in the new factory is the expansion of its lathe division, which is expected to increase the part processing capacity of Chinmore by at least 20% to 50% and optimize the support and service Chinmore could offer to global customers.

Chinmore President Tien-Din Wang said, “Considering the increasing customers’ demand and in order to meet customers’ required order volumes and lead times, expanding our division and introducing more machines are requisites. As a result, we not only expanded the scale of our factory, but also purchased processing machines with higher precision from abroad in order to satisfy customers’ stricter requirements for more precision parts. Through the re-upgrade of scale and capacity, we wish to establish good reputation in the global market and make customers gain more confidence in our products!”

Integrating Manufacturing with Advanced Machines

High Quality and Efficiency

“Being able to manufacture customized high quality lathed parts for customers in the most efficient way” has been followed by Chinmore as its quality policy for more than 2 decades. With persistence in quality and manufacturing efficiency, Chinmore introduced many world’s most advanced automated/semi-automated CNC lathes and injection molding machines and spared no expense to introduce Japanese automated CNC lathes. Moreover, its in-house professional engineers would also carefully review submitted drawings, demand or application requests and discuss with customers and have them manufactured by well-trained operators, which is why Chinmore’s products could always exceed customers’ expectations in terms of precision and performance. Through the support of precision equipment, Chinmore could quickly process any OEM and ODM demand and has established close partnership with many European and U.S. customers.

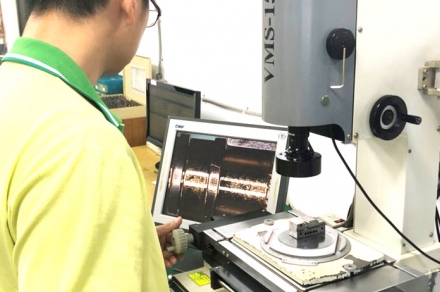

Chinmore’s customers are mainly from the telecommunication industry and they are in urgent need of a supplier who has capabilities of function integration, batch-by-batch supply, reducing inventory to the lowest, quick response, small-lot production with a variety of items and offering the lowest cost. Accordingly, Chinmore, which keeps introducing automated facilities and precision quality inspection devices for consistent product specifications and better quality control, becomes the best option of all.

Adopting Complete SOP

Awarded ISO9001:2015 and ISO14001:2015 Certification

Another part which Chinmore feels quite confident is its standardized and efficient manufacturing procedures. From material selection, feeding, processing, testing, inspection to the final shipment, Chinmore has its own SOP. In addition, it has also introduced automated 3D projectors to do further inspection in order to ensure quality consistency of each product in every manufacturing step. As the entire team makes no compromise over each detail, Chinmore has been successfully certified by ISO 9001:2015 and ISO14001:2015. Chinmore’s quality has been clearly revealed by its fast & efficient manufacturing procedures and stable quality of its finished products.

Chinmore contact: Ms. Mandy Wang

Email: mandy@chinmore.com.tw

Subscribe