ZinKlad ensures global consistency at a local level

MacDermid Enthone Industrial Solutions contact in Taiwan:

Leo Ou, Sales Manager

Email: Leo.Ou@MacDermid.com

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

The ISO 9001:2015 certified ZinKlad program is a quality assurance system developed by MacDermid Enthone Industrial Solutions (MEIS) of MacDermid Performance Solutions (a team consisting of 4,500 well-trained employees and engineers with expertise in surface finishing across 50 countries). Established since 1922, MacDermid Enthone is dedicated to offering high performance chemical processing solutions/chemicals/materials and unrivalled knowledge of excellent surface finishes for automotive, aerospace, construction, oil & gas and many other safety critical industries.

What does MacDermid Enthone Industrial Solutions Do?

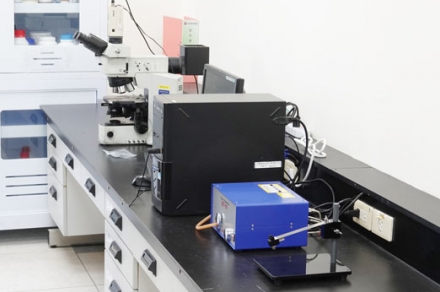

As a globally recognized company offering localized service for critical industrial applications, MacDermid Enthone Industrial Solutions has 18 technical centres, 10 R&D centres and 15 manufacturing locations around the world as well as a select team of experts and engineers specialized in specific surface finishes for global OEMs and customers worldwide. Currently, MacDermid Enthone Industrial Solutions has around 80 approved applicators in 17 countries (subject to change after regular audits), which all play key roles in ensuring that the service/products provided by manufacturers are 100% compliant with stringent requirements specified by OEMs across different regions/markets. In southern Taiwan, where many industries (fasteners, for example) have urgent need of efficient and cost-effective corrosion resistance, MacDermid Enthone Industrial Solutions also has an Advanced Application Lab (AAL) to introduce advanced technology and latest industrial standards specified by global OEMs and provide timely technical service and product R&D to support customers' business strategy. ZinKlad is one of these many systems introduced by MacDermid Enthone Industrial Solutions particularly to automotive relevant applicators to maintain the highest manufacturing standards.

Benefits of ZinKlad for Global OEMs and MacDermid Enthone Industrial Solutions Applicators

Developed for more than a decade, ZinKlad has been considered an optimum choice that helps tackle future challenges for high performance automotive coatings (e.g. strict requirements for non-hexavalent chromium, cadmium, lead, or any other volatile organic substance-free coatings). This system continues to evolve steadily, enabling global OEMs to specify higher performance standards and approved applicators to provide real-time service fully satisfying the ever-changing needs of global OEMs. ZinKlad has been extensively proven in the automotive fastener industry, in which corrosion resistance continues to be a critical factor in maintaining high performance. Under the program of ZinKlad, regardless of where the service is provided or who is offering the service, the coatings are the same, the performance is consistent, and the compliance with legislation (e.g., ELV, RoHS, REACH, etc.) is maintained at all times!

"Specifiers require higher performance, so MacDermid Enthone Industrial Solutions has been working diligently to develop even more solutions for our applicators. Globally, we also support our applicators to operate their processes to run as efficiently as possible, and most importantly to meet or in many cases exceed the global OEMs standards. Today, we lead the change for plating for zinc-nickel, tin-zinc and cobalt-free coatings. In our ZinKlad program, we offer global consistency at local level, meeting OEM requirements with a selected number of world class applicators," says Lammert de Boer, Global Director of MacDermid Enthone Industrial Solutions ZinKlad, DecoKlad & XAPP.

Various ZinKlad Levels for Specific Needs

Each portfolio of the ZinKlad system consists of zinc, zinc alloy, trivalent passivates, topcoats and lubricants applied by MacDermid Enthone Industrial Solutions approved applicators in the relevant coating that fully satisfies the required surface finishes of many global leading OEMs (e.g. BMW, Bosch, FCA, GM, PSA, etc.). The levels of ZinKlad have been extended to include ZinKlad (72, 96, 250, 250M, 500, 500B, 750, 1000, 1000B, MG/MGL) in barrel applications and ZinKlad (240, Brake 240, Brake 1000) in rack applications.

MacDermid Enthone Industrial Solutions applicators are a network of experts in surface finishes selected by MacDermid Enthone Industrial Solutions global OEM team. They are approved to fully meet Tier-1 and OEM needs. “However, becoming an approved applicator of MacDermid Enthone Industrial Solutions requires applicators to meet a very high standard of process control and deposit testing and the number of applicators is limited,” added Lammert. For example, MacDermid Enthone Industrial Solutions now has 7 applicators in Taiwan and these applicators are regularly audited and required to take performance tests. ''We make every effort to ensure that every applicator approved by us is compliant with the requirements of global OEMs. As a result, we allow no change in processes of our ZinKlad system and also would provide any possible support to applicators in case of problems. If any applicator unfortunately could not pass our audits in the end, after serving a probation period to rectify issues, we have no choice but to remove them from our approved applicators list," noted Lammert.

Making Improvements with MacDermid Enthone Industrial Solutions ZinKlad

MacDermid Enthone Industrial Solutions never stops working with global OEMs’ to develop products meeting their expectations and introducing higher performance standards required by OEMs’ to customers in relevant industries (e.g. inviting a speaker from M. Benz to introduce MBN-10544 at the Global Fastener Summit in Kaohsiung this April). Through the development and use of ZinKlad, the connection between OEMs and customers can be firmly established and reliable & consistent service can be maintained and available worldwide.

Lammert added, "Continuous success and sustainable development of our valued customers’ businesses are important to MacDermid Enthone Industrial Solutions, so we are very pleased and definitely have capabilities to support and guide our customers to carry out the ZinKlad quality assurance system in their processes, helping them establish solid connection with the global OEMs and achieve the highest manufacturing standards in every concerned aspect of the industry."

Subscribe