Cheng Fang Yuan Machinery’s Auto Thread Tapping Machines - Strike the Market with Excellent Performance

The Dadu, Taichung-headquartered Cheng Fang Yuan Machinery Industrial Co., Ltd. (“CFY”) is a manufacturing expert of precision nut tapping machines in Taiwan. Its products include Auto Thread Tapping Machines, Arraying/Filling Feeders, Nut Cleaning Machines, etc. It is also capable of developing relevant parts for automatic machines to satisfy the eagerness of global customers for less pollution, low noise, reduced energy consumption and increased added value of products.

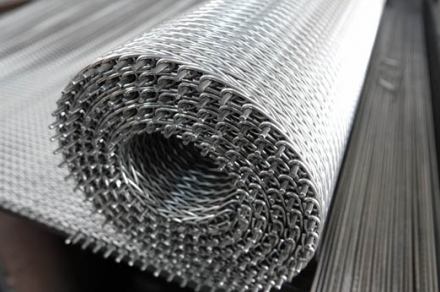

Efficiency and Quality of Thread Tapping Machines are Enhanced

Thread tapping machines currently operate with two processing phases, which play a key role in making perfect internal threads. Traditional thread tapping machines tap threads at the consistent speed and such a way may shorten the service life of taps. However, if the speed is lowered to prolong the service life of taps, the manufacturing efficiency will be reduced instead and rough thread surface may be generated. In order to solve this dilemma which has bothered the industry for long, CFY taps threads at low speed in the 1st phase and trims threads at high speed in the 2nd phase, which substantially increases the accuracy of threads and prolongs the service life of taps without sacrificing the capacity. President Lai said, “Taking the lead in technology is our goal and our technique is innovative in the industry.”

High Quality Spindles That Help Increase Machine Durability and Save Energy

Lai noted that other tapping machines are often reported to have too short service life of spindles. The spindle is the most essential part in the machine. If not dealt with properly, the entire manufacturing process may unexpectedly stop, or the processing cost may hike due to frequent replacement of spindles. CFY’s tapping machines demonstrate several advantageous features. For example, the centrifugal spindle design makes machines operate durably and not give out a lot of heat and is energy saving as well. Their service life lasts much longer than those of similar models. Some customers’ machines have operated for more than 2 decades even though they are not put into regular maintenance.

The Easy-to-use and Stable Functions Make CFY the Designated Supplier of Leading Nut Manufacturers

Many domestic and overseas leading nut manufacturers have been collaborating with CFY for years. As these companies always have piles of order books and a long list of delivery schedules, they need a type of machine to help them achieve faster processing, maintain precision, stability, and price competitiveness. Accordingly, CFY, which has all the aforesaid three features, has established long-term collaboration with these leading companies. On the other hand, some high-end nut manufacturers from USA, Japan, France and Korea as well as automotive nut manufacturers from China, India, Indonesia, Vietnam, Thailand, Turkey, Hungary, Mexico and Brazil have also turned to purchase machines from CFY due to recommendations of the big brands.

President Lai said with confidence, “Positive feedback from customers is the biggest encouragement to CFY. For years, we have been well-known for our technique and customizing capabilities for customers. Our products were once patented and have been CE certified. Considering the future market demands, we expect to offer reliable and high-performance tapping machines to customers through continuous effort in R&D.”

CFY contact: Ms. Kuanling Lai Email: cf6666@ms71.hinet.net

Subscribe