TIGGES Taiwan Branch The Symbol of High-end Technology, Precision and Quality

by Dean Tseng, Fastener World

TIGGES is a family business founded in 1925. The family has passed the torch to the 4th generation, and now TIGGES is among the primary special fastener makers in the world with thousands of clients. Furthermore, with its acquired aerospace certificate, it has taken Airbus orders and strengthened its roots in the European market. It has the advantages of integrating cold forming, machining, grinding and hot forging into a one-stop workflow, providing customers with project management, R&D, die making and quality control to exert highest production flexibility for each individual product. In 1990, the headquarters set up a plant in Malaysia on par with German quality standard. 2009 marks the year of establishing a sales office and warehouse in Kobe, Japan to expand business to the world market. In 2013, the headquarters took a step further and set up a sales and logistics office in South Carolina of the U.S. Today, the “TIGGES” brand is proliferating its presence in the U.S., Europe, Asia and the emerging Southeast Asia.

TIGGES Taiwan Branch - Purchase/QA/Sales All Rolled into One; Quality & Technology in Sync with German Level

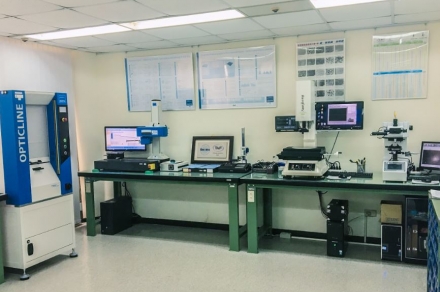

When it comes to TIGGES, you do not pay little attention to its extreme self-requirement on high-end technology and customized service. Fastener World news team visited its Taiwan branch, and what came into sight were a long experienced team of fastener QA specialists and a full-fledged laboratory. The QC equipment included a Japanese hardness gage, a 2.5D visual measurement gage, roughness gage, ring gage, and German contour gage. Among them is a notable ultra-precision quick gage capable of 360-degree self-rotary scan and generating data reports. Miss Carys Lin, head of TIGGES Taiwan Branch, said the company does not manufacture standard parts, but specializes in high-end special parts in various materials and at high unit prices. These special parts are fully customized to customers’ drawings, of which 50% are automotive parts. TIGGES Taiwan has a local assembly plant supplying bike fasteners to the domestic market. Additionally, the company is certified to ISO9000/2015 and ISO/IEC 17025. It has collaborative partners in Taiwan and can directly communicate with clients through video chat. As Carys mentioned, the reason that TIGGES chose Taiwan is because it spotted the integrity and technical capability of Taiwan’s fastener supply chain that can help it avoid price, quality and cultural communication problems derived from purchases through traders.

Current Target Market: China

Through the Taiwan branch, Carys said she is actively extending the headquarters’ reach into China. Regarding the Chinese market, she stressed the biggest difference between TIGGES and other common traders are its 5 steps of quality assurance. First, TIGGES Taiwan directly adopts QMS from its German headquarters, and holds APQP meetings with clients to ensure barrier-free communications. Second, its QA staff will head to the factories for quality check to reduce misperception on drawings. Third, they will communicate with technicians on the site and perform measurement after production. Fourth, they will do a full size inspection on finished products including automotive and non-automotive parts. The final step is providing samples and shipping.

Other strengths of TIGGES are speed and efficiency. In our interview with Carys, she shared her insight that the current China market does not compete on technique but rather speed and reaction. Delivery used to take 60 days including a month of wire purchase and another month of making dies. However, this has changed because the increasing number of billionaires in China led to much faster replacement of cars and components, so much so that China’s cars now are required to have only 1-2 years of durability. Therefore, she noticed there have been more and more urgent orders from China. Thanks to plenty of stable partners, the fastest record that TIGGES Taiwan has ever had is submitting samples within a month and winning China’s orders.

The third strength of TIGGES is its advantage in local culture. TIGGES deeply understands the difference on purchasing habits between the Chinese and Europeans. The Europeans usually purchase from factories through middlemen, while the Chinese prefer directly purchasing from factories to factor out the complexity that may come with the middlemen. Due to relatively higher prices with Taiwan’s fasteners and China’s preference for localized purchase, the Chinese buyers are most of the time unable to change suppliers. Even so, they still import A and B-class parts from Germany when they need high-end fasteners. Carys thinks this is the entry point for TIGGES. TIGGES can directly supply to end users including those Chinese buyers. As she stressed, TIGGES has taken root in China since 2013, focusing primarily on automotive clients and supplying automotive safety and non-safety parts. In the future, TIGGES will expand business to the medical, aerospace, machinery and industrial fields. To Chinese business owners that need to purchase directly from factories, TIGGES Taiwan is among the few that can directly supply to Chinese end users. Therefore it does not need to go through secondary processing by Taiwanese factories in China or others before it delivers to end users. To all Chinese automotive clients that TIGGES Taiwan have delivered to, the company can manage makers of various techniques for clients. All it takes for clients is to contact TIGGES Taiwan and rest assured that this will save them tremendous time and labor cost.

On the Status Quo of Taiwan Fastener Industry

As we were closing the interview, we were curious to know her views and suggestions for Taiwan fastener industry in the overseas business perspective. She pointed out, “The time has changed. Taiwan should not just seek ‘large volume’ fastener production. The world’s industry structure is changing, and the shift to a higher end is an important trend. This is especially true to the automotive market where Taiwan has quite a large number of automotive OEMs, but some of them are not catching up with the perspectives and requirements of European carmakers. The keys to a successful shift for Taiwanese fastener companies are the change of mindset, technical capability and communications during service.” Her insights provide a reference for Taiwanese fasteners, and we hope TIGGES will mark another success in the global market in the future.

TIGGES TAIWAN BRANCH

Rm. F, 20F., No.7, Siwei 4th Rd. Lingya Dist., Kaohsiung City 802, Taiwan

Tel: +886-7-536 6889 Fax: +886-7-536 5878

E-mail: jla.tw@tigges-group.com

http://www.tigges-group.com

Subscribe