Best Cold Forging Former Manufacturer & Business Partner Biing Feng Enterprise Co., Ltd.

Biing Feng seeks to achieve continuous improvement of the company! Its abbreviated name, BF, can stand for “Best Former” or “Best Friend,” which implies that Biing Feng is the best cold forging former manufacturer and the better business partner that grows with clients. Biing Feng has been more than 40 years since 1976, which has got a foothold in the market of nut and part cold forging formers in terms of quality, technology or experience.

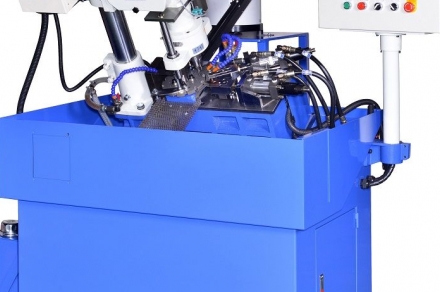

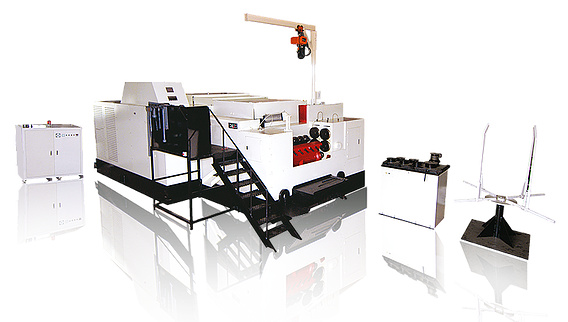

Biing Feng’s machines are categorized into 3 types: Standard, Long Stroke and P.K.O. Among them, the most popular ones are 14B to 33B formers (applicable to M8-M22) under the P.K.O. series. In response to the trend of automated manufacturing, clients are making fastener products with more and more complicated designs and gradually elevated requirement on precision. Compared to other general formers, the P.K.O series have an additional punch kick-out function to further satisfy clients’ needs. Biing Feng’s cold forging formers are applicable to the industrial sectors from furniture, construction, automobiles/motorbikes to aerospace. Its equipment has been sold to 32 countries worldwide, and in recent years mainly sold to markets like Europe, East Asia, Southeast Asia and America. According to Biing Feng’s conservative estimation, the global machine sales of Biing Feng as of the 1st half of 2016 have been over 5,200 sets.

In 2014, Biing Feng finished the construction of its second plant and expanded the production line. Last year the construction of another new plant was also started and is expected to be completed this year. The new plant will not only provide employees with a more comfortable working environment and usable space, but will be also able to handle the increase in orders. The administrative unit is also planning to build a new office building. In the era with increasing concerns about environmental protection, Biing Feng has had solar panel power systems installed on the roof of its whole plant to make its own contribution to environmental protection.

Reasonable Prices and High Quality as Other European/US/Japanese Counterparts

Compared to other similar domestic and overseas companies, the most recognized feature of Biing Feng is its machine stability, durability, maintenance, and good operability for users, resulting in a high machine availability/uptime for users. With reasonable prices, good after-sales service, client-oriented approaches, and persistence to its mission statement, Biing Feng always treats clients as its most important friends.

Industry 4.0 and Intelligent Manufacturing have boosted changes in clients’ needs. Facing the changes in demand, Biing Feng’s equipment can be customized according to customers’ needs and go with additional functions, such as servo-controlled feeding systems, die micro-inch movement calibration systems, inverter installment, forging inspection systems, and rapid die-switching systems. In recent years, Biing Feng has rolled out 8-dies equipment, providing clients with more advanced manufacturing capabilities. Its primary goals for the future are continuous R&D and innovation, mutual growth with clients against challenges, and client satisfaction.

Continuous Progress with Times

In the industry with fierce competition, it is essential for a company to progress with times, in order to continuously be on the forefront of the industry and in order not to be eliminated. With regard to distribution routes, Biing Feng has redesigned its website and had its own FACEBOOK page this year. It not only promotes itself on fastener and machinery magazines, but also actively exhibits or visits shows to increase its exposure, visit clients and increase opportunities to meet customers face to face. Regarding after-sales service, it tries its best to predict what problems clients may face and what they may need, and offer machine operation manuals at the time of shipment to help clients know how to operate the machine immediately upon receipt. Additionally, when clients submit their feedbacks, it will offer them professional advises based on its years of technique and experience in specialized cold forging former production and will do whatever it can to listen to clients, satisfy them and grow with them, as Biing Feng always offers the “Best Former” and is their “Best Friend!”

Biing Feng contact: Mr. Lance Wei (email: bf@bestformer.com)

Subscribe