Dimac Srl

Blue Ocean of Industry Leading Players: Dimac Srl

dimac is a family company established in 1988. Since the early 1990s the automotive industry has been the driving force of the highest technology developments. All the automotive companies needed to improve the production processes as well as the overall product quality, growing their business while reducing manufacturing costs. These goals have also been pursued by pushing the fastener manufacturers towards the production of parts with zero defects. dimac then realized that it was the time and the place for high-tech suppliers in the market to adopt automatic 100% inspection and sorting machines to support the production of automotive fasteners with zero defects.

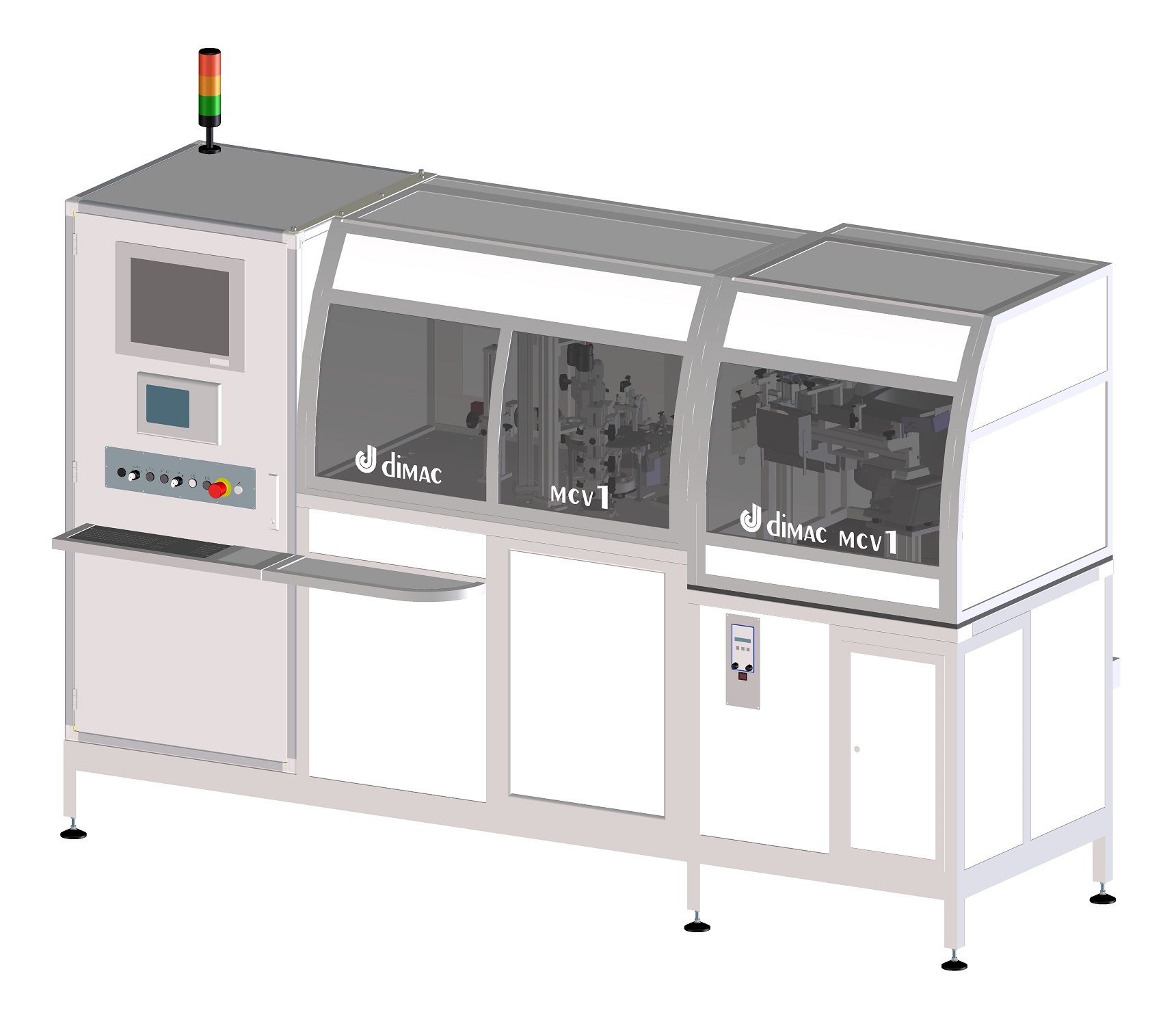

The first prototype of the rotary table inspection machine MCV1 was a success and was the first time that a high-tech automatic machine made in Italy with Italian design could perform high-speed 100% inspection and sorting of a wide range of products, with high-precision 360° dimensional controls by high-resolution cameras and inspection of several attributes such as mechanical gauging and NDT controls for crack and heat treatment. Now dimac offers 8 different types of machines, with different feeding systems and inspection stations suitable for a huge range of fastener typologies.

dimac’s average volume is 3.5 million €/year. Its end-user companies are all around the world for automotive, aerospace, industrial, railway, medical and furniture manufacturing applications. Its major markets are Europe, USA, Turkey, and Brazil and customers are mainly automotive fastener manufacturers but also automotive fastener resellers/distributors and importers/exporters. 5% of dimac’s machines are sold directly to fastener assemblers and end-users. dimac’s automatic 100% inspection, measuring, and sorting machines (MCV1 and MCV2 models) are TÜV certified.

dimac estimates to raise cooperation with other partners in emerging markets (especially China and India) in 5 years probably and wishes to find new customers among manufacturing leaders in automotive fastener supply. For the moment dimac sells its machines to some European fastener manufacturers who have plants and joint ventures in China and India. dimac expects that the MCV (equipped with a user-friendly system, fast, 24/7 usable without additional costs, monitoring the inspection results data, improving line efficiency) could well respond to the automotive needs of emerging markets.

dimac’s policy is to invest in R&D and that’s the priority to keep dimac’s leadership in the fastener market. Then, for sure, it’s also essential to strengthen the reliability of its products by using only top quality components. Last but not least, the goal is to carry on improving dimac’s service to satisfy its customers with short-time answers and prompt on-demand online assistance.