Industry Activities

Multiple-stroke Cold Forged Parts Maker - Hsin Jui’s New Plant for Doubled Capacity and Revenue

Add to my favorite

2013-11-15

It took only 4 months to complete the planning, renovation, new equipment procurement, relocation, positioning and formal production operation for the 5,400㎡ factory of Hsin Jui Hardware Enterprise Co., Ltd based in the Guishan Fourth Industrial Zone, Taoyuan County. “This relocation was very difficult, it could not have been possible without the concerted efforts of the plant manager and all the employees who computerized the dimensions of all the equipment,” said Managing Director Alan Hsu, “through countless discussions and revisions, we were able to position the equipment accurately all at once. The completion of the new plant is not only a new milestone, but also an important process to cohere the employees.”

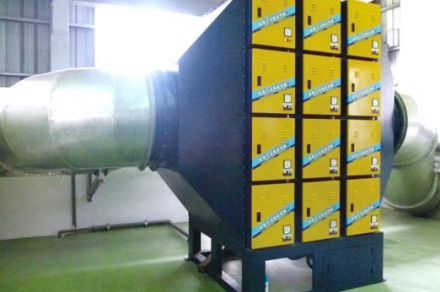

Substantial Investments in Production, QC and Eco-friendly Equipment Make

Hsin Jui the Symbol of “Technology, Quality, Sustainability”

Hsu recalled the establishment of Hsin Jui in 1980 when he was 25. He raised NTD200,000 from his parents to start the business. After spending on the rent and deposit of the 66 square meters plant, he did not have much left and could only afford two second-hand screw formers. Being disadvantaged in equipment and production capacity, Hsu decided to produce high value-added products such as tubular and hallow rivets to offset the unfavorable condition by remodeling the screw making machines. Hsu even faced several crises of closure during the startup period, for he spent too much time on developing and improving equipment and had no energy to take care of production. “However, I have made it through the hardship,” said Hsu with gratitude, “ thanks to the help of many of my friends and relatives.” Now, after 30 years of hard work, Hsu has purchased 16 multiple-stroke cold forging machines. To meet the requirement of the new plant, another 7 units have been added, totaling 23 machines.

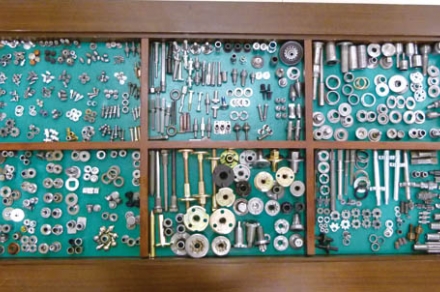

Moreover, in view of the customers’ increasingly high demand for quality, Hsin Jui does not only pursue the techniques or products far ahead of the market but seeks a balance between R&D and quality. The newly purchased computer grading machine, optical projector, tensile machine, power discharger, wire cutter, computerized grinder and 3-D drawing software have given impetus to the company’s development in the fields of hardware and fasteners. In its 33-year history, Hsin Jui has always demonstrated very strong ambition.

Self-owned Molding Department is

the Technical Core of the Company

It’s very hard to imagine that a hardware and fastener manufacturer has its own “mold development department” just because the managing director believes that molding is the technical core of a fastener maker and such technology should never be disclosed to outsiders. Encouraged by his customers, Hsu began to learn 3D drawing software such as AutoCAD and SetchUP 25 years ago when he found himself confined in on-site operation after the hand injury in a car accident. The learning has not only boosted the R&D capability in a dramatic way, but also achieved higher management efficiency of the plant.

While cold-forged products are required to have higher precision and need to be completed in a very short time, Hsin Jui boasts its expertise in multiple-stroke cold-forged parts and specializes in the special components of automobiles, motorcycles, building hardware and all other fields.

With the completion of the new plant and upgrade in hardware and software, Hsin Jui plans to increase the current number of employees from 35 to 60. The company will also penetrate into the promising bicycle parts and accessories market. With a vision for the global market and vibrant energy, Hsin Jui will maintain relationships with the long-term clients in Europe, USA and Japan and make plans to multiply the production capacity and revenue.

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD