Industry Activities

Ningbo Geobo Hardware Expanding Non-standard Parts to South America

Add to my favorite

2023-06-21

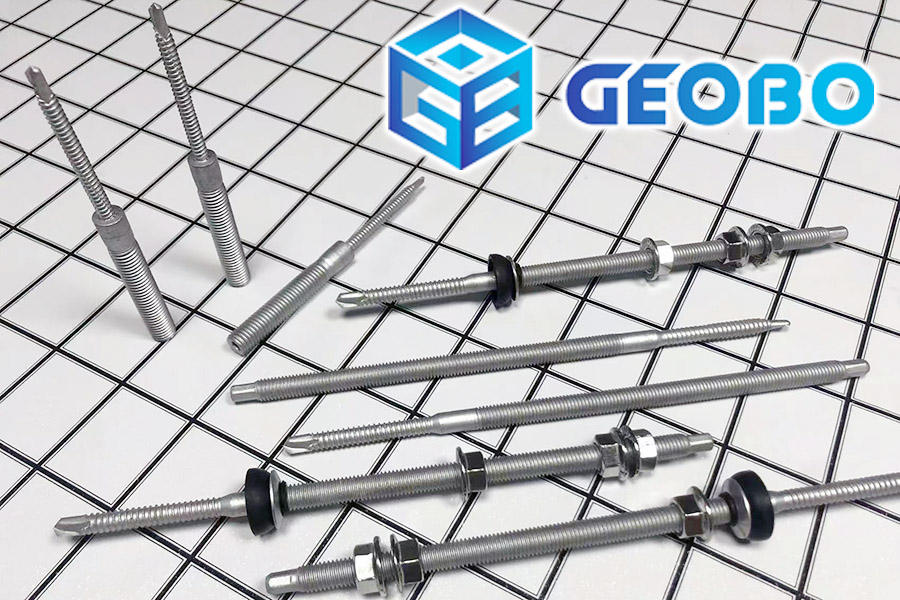

Kerry Tu started in 2008 as a customized fasteners manufacturer for domestic clients. Then in 2012, he established Geobo and transitioned to international fastener trade. Over the years, his business has grown significantly, and by 2019, he had expanded his operations to include a bolt and a screw factory, and a broad range of products. With a production capacity of over 5,000 tons annually, now he owns more than 80 automated machines, including cold-forging, threading, and punching machines, to manufacture standard and customized bolts, screws, stamped and machined parts, and non-standard parts in various materials such as carbon steel, alloy steel, stainless steel, copper, and aluminum. Additionally, construction fasteners account for about 70% of his total export value.

To ensure quality control, he has set up a testing laboratory that assesses dimensions and performance of products and has passed ISO9001 quality system certification. With a do-it-yourself packaging plant spanning over 6,000 square meters, he offers a variety of fasteners to clients worldwide.

Core Competence: Non-standard Parts Production

Geobo has an R&D team and advanced manufacturing equipment enabling them to provide professional sample production services. They work according to customers' drawings and samples and cover product strength grades of 4.8 to 12.9. Additionally, they offer a wide range of surface treatment options, such as galvanized zinc plating, nickel plating, copper plating, mechanical zinc plating, Ruspert, Decromet, Magni, HDG, and lock glue.

Their packaging plant provides various materials and forms for do-it-yourself product packaging to ensure the products and packaging meet customers’ quality and appearance requirements. Product quality and on-time delivery are of utmost importance.

They have a strict quality inspection system equipped with high-precision inspection equipment which allows them to test products for tapping speed, salt spray resistance, hardness, and torque. They also use full-inspection optical sorting equipment and high-precision dimensional measurement projectors. They conduct regular random checks, precise checks, and third-party inspections to ensure meeting high-quality standards.

Great Sidekick for Photovoltaic Industry

The market has increased demand for cleaner energy, leading to exponential growth in the photovoltaic energy economy. The company produces some of the photovoltaic fasteners itself and keeps intimate cooperation with factories manufacturing other metal products, so they quickly enter the photovoltaic parts field and provide one-stop procurement service and quality assurance for foreign fastener wholesalers and solar panel mounting enterprises. They can also provide professional consultation and product support for overseas enterprises interested in entering the photovoltaic industry.

Expanding Sales to South America in 2023

Europe has been the driving force behind their overseas sales, but they're not stopping there. This year, they have ambitious plans to expand into new territories, such as Mexico, Brazil, and other South American markets, with optimism for the potential of South Africa. It's worth noting that they have already achieved a remarkable feat by exceeding last year's sales figures by 50%. They will maintain focus on key products such as outdoor and roof fasteners, stainless steel fasteners, and photovoltaic products. Kerry summed up: "Quality is the foundation of any successful company. Despite being in the basic fastening industry, we know product quality remains the bedrock of our steady progress."

Contact: Kerry Tu

Email: info@cngeobo.com

寧波卓邦金屬

非標緊固件

螺栓

螺釘

DIY包裝

光伏產業

Ningbo Geobo Hardware

non-standard parts

bolt

screw

DIY assembly

photovoltaic industry

Industry Activities

2023-06-26

Subscribe