Industry Activities

by Dean Tseng, Fastener World

SGE has stood for 30 years since it was founded in 1988. It operates on the core belief of “Service First, Guaranteed Quality, Top Efficiency”, producing professional terminals and supplying to global industrial and DIY markets. Its products are UL/CUL certified and adopted by renowned companies in Germany, UK and other countries. The main products are ring terminals, spade terminals, connectors, cord-end sleeves, etc. It had another breakthrough in 2016 with its newly-acquired patent and started sales of the patented product last year.

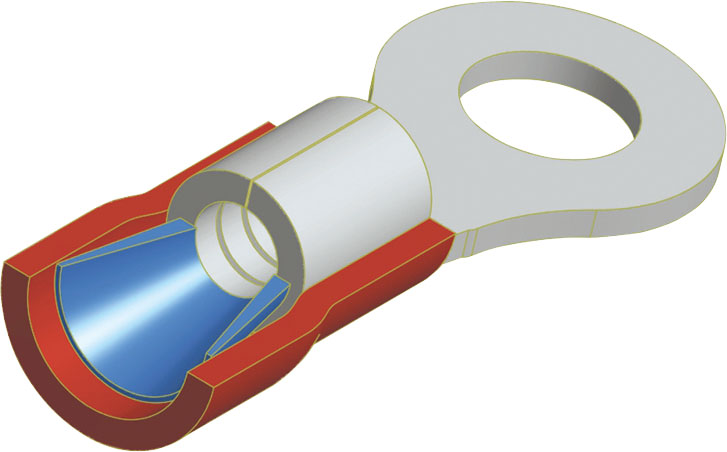

Patented Easy Entry Terminal Boosts Electric Wire Load-up Speed and Convenience

The wire entrance hole of a general standard terminal, due to its width, is likely to cause the electric wires to split during wire insertion. More often than not, only 15 out of 20 electric wires can be fully inserted, which is likely to degrade conductivity. To avoid wire splitting, some users may choose to pinch and twist the wires and then insert them, but pinching and twisting already waste half of the time. With a patented design, SGE’s Easy Entry Terminal allows the electric wires to put together easily and go in the wire entrance hole at once.

The inventor, president Ken Li, who conceived this patented product, has more than 20 years of experience in the terminal industry. In an exclusive interview with Fastener World Magazine, he detailed on the features of this product. First, it saves the trouble of wire split, accelerates wire insertion, and improves convenience for users. Second, the users can only insert 5,000 electric wires per day with general terminals, but with SGE’s Easy Entry Terminal they can insert 10,000 wires, which translates to 50% time and workforce saving. Last but not least, it is highly price-competitive with 20% lower price than its counterparts on the market. President Li said the sales of his patented product has grown 10% to 15% since its launch and his target is to tap into the world market.

2nd Generation En Route to Stable & Proactive Marketing Strategy

According to president Li, back when his father started SGE from scratch, his father took a stable and conservative approach on the business and developed products as per clients’ existing and actual demands. After he took over from his father, he took a stable and proactive approach. It means the company has to not only respond to clients’ existing demands, but also conduct research on market demand, make assessment on feasibility and risks, tone up sensitivity to market development, and finally be able to predict and create demands that may interest the clients. Furthermore, he brought SGE to the world market by exhibiting at industrial fairs in Hannover, Spain, etc. This September the company will attend MDA and Industrial Automation in Chicago.

Relocation Next Year with Greater Capacity

President Li revealed that SGE will relocate to a new plant near the Changhua Interchange in Changhua City (Taiwan) at the end of 2019. He said the company has purchased a 2,545m2 industrial land. In phase 1, the new plant will have 2 floors that will increase the total plant area to 3,306 m2. With the future plant expansion, SGE will purchase new equipment. The future of SGE is bright with positive expectation as president Li continues to bring changing innovation to the company.

SGE contact: President Ken Li E-mail: sales@sge.com.tw

Subscribe