Industry Activities

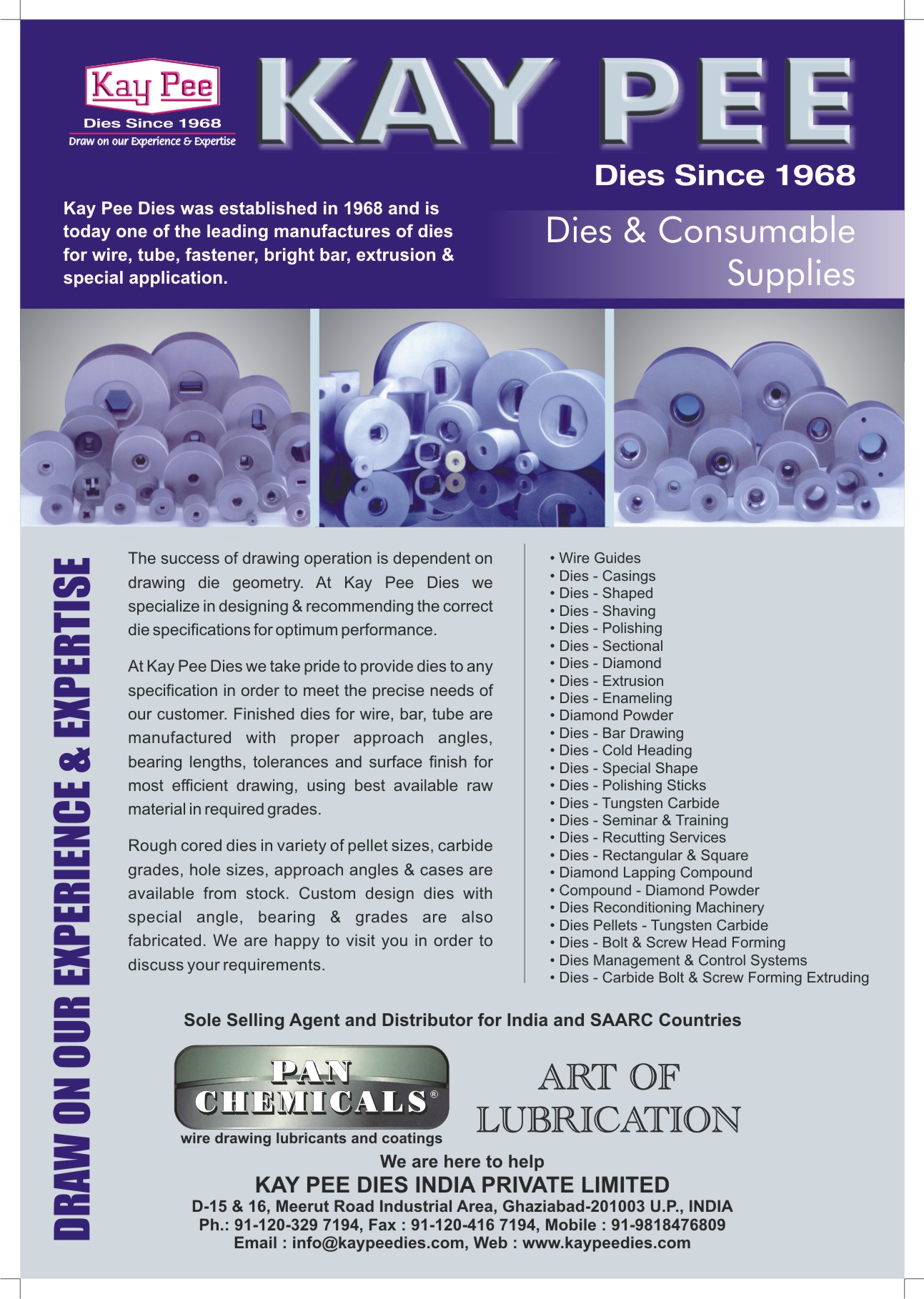

With its inception in 1968, the Ghaziabad, India-headquartered Kay Pee Dies, as its name implies, is a half-century old company specialized in the production and supply of high quality and durable tungsten carbide dies and wire drawing lubricants mostly used in fasteners, wire and related industries and applications. Founded by Mr. Harish Jindal, Kay Pee Dies has thus far achieved several successful results and amazing business performance in India’s tungsten carbide dies industry, earned an industry-recognized reputation and is celebrating its 50th anniversary in 2017. Though facing so many challenges ahead and fierce competition from around the world, its business turnover continues to be on the significant rise every year.

The Industry Pioneer in India

Before becoming the pioneer of manufacture of tungsten carbide dies in the Indian industry, the founder Harish Jindal worked at leading India Hard Metal Pvt. Ltd. Kolkata and was in charge of technique development and manufacture of tungsten carbide dies, which later offered him a wealth of experience in the specific industry and made him able to initiate his own business at the right time. Prior to the establishment of Kay Pee Dies, most of the carbide dies demanded in the Indian market were mainly supplied by Wimet UK.

Irreplaceable Product & Service Offering

With the vision of “being the leader in India’s die industry and establish a healthy and constructive partnership between die users and the manufacturer,” Kay Pee Dies only uses the best quality of tungsten carbide available in the Indian market to produce molds that best suit customers’ needs and requirements, which is why Kay Pee Dies can always take the challenges and be outstanding to win customers’ trust.

“Kay Pee Dies is managed by two qualified engineers (one has 58 years and the other has 16 years of experience in the industry). We also constantly upgrade our processes and innovate new products with regular visits and participation at wire shows around the world, such as Germany, USA, China and Thailand. In addition, we have a very high track record of retaining our customer base due to our irreplaceable quality, delivery and personalized service,” Director Asim Jindal proudly says.

More International, More Collaboration

A great proportion of Kay Pee Dies’ customers are from local India, however, Kay Pee Dies still has around 20% of its sales generated from the export to the surrounding countries or regions such as Nepal, Vietnam, the Middle East and Africa. The leading position of Kay Pee Dies was further strengthened after it built up a solid business partnership with Italian PAN Chemicals SpA in 2008. Since then, Kay Pee Dies has become more international company, which not only focuses on the local Indian market but also the potential world market.

“Kay Pee Dies entered into a sole agreement with M/S Pan Chemiclas S.p.A., Italy for sale and distribution of their worldwide accepted wire drawing lubricants and surface coating compounds in India and SAARC countries. During the last over 8 years of this fruitful partnership we are now selling huge quantities of their products in a year and a faith and trust has been established to the extent that a proposal is under negotiation to start selective manufacturing of their products in India in joint technical and financial venture. This will save on freight and custom duty which account for roughly 25% of the landed cost,” Director Asim Jindal noted.

The In-time Solution Provider

With the current huge demand for TC dies in India and the problems of short availability of quality dies and companies having foreign collaborators are recommended to import dies being used in collaborators’ units, Kay Pee Dies could definitely play an essential role in promptly fixing these problems and providing its customers with the most appropriate solutions at all times. Kay Pee Dies is looking forward to an annual compound growth of 15-20% by supplying quality dies at the most reasonable prices and high-level service.

Director Asim Jindal concluded at the end of the interview, “While evaluating a die, cost per ton of product produced, cost of changing dies and consequent machine down time should also be compared/evaluated. Die suppliers are your partner in proper selection and usage of dies and Kay Pee Dies is always ready to offer their services in this direction.”

Kay Pee Dies contact: Asim Jindal (Email: asim@kaypeedies.com)