August Featured Companies: Linkwell Industry / King Yuan Dar

【Likwell weathers market turbulences through stable supply. / King Yuan Dar launches "Cyclic Continuous Vacuum High Temperature Sintering Furnace" incorporating more features】

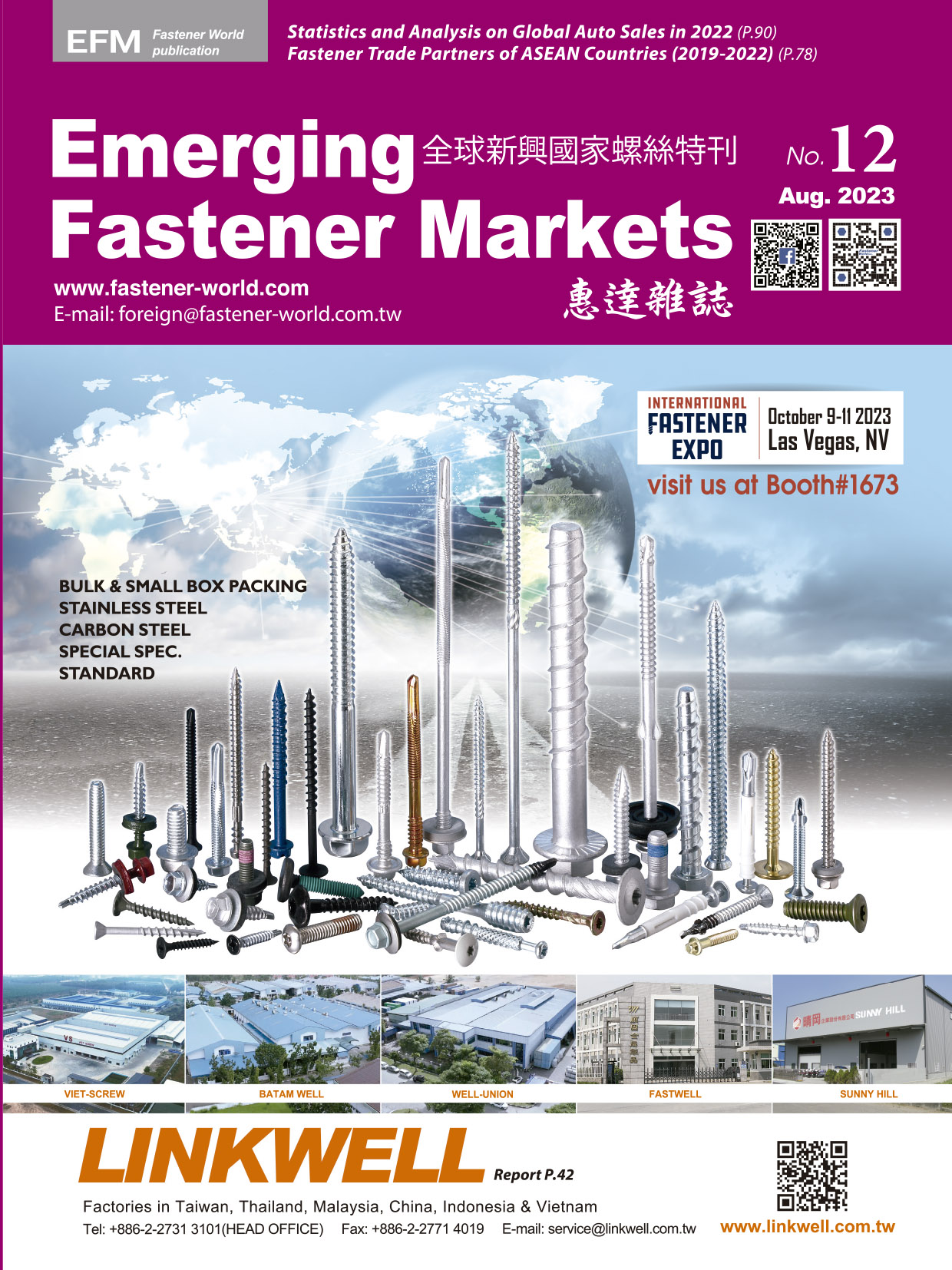

One-stop Manufacturing + Multi-Locations Linkwell Industry - Reliable Support for Global Fastener Demand

One-stop Manufacturing Process

As one of the early-established fastener traders in Taiwan, Linkwell has successfully crossed over to fastener manufacturing and can provide a complete production flow including wire drawing, forming, heading, tail clamping, thread rolling, tapping, degreasing, heat treatment, plating, coating, quality inspection, and packaging. They have mastered one-stop production and have access to traders’ fastener supply routes.

Over the past 46 years, they have weathered various market turbulences through resilience reflected in their stable supply. Linkwell has a reputation for their reliability and Taiwanese high quality, supplying to customers in the machinery, automotive, and construction industries in various countries. Linkwell has factories in Vietnam, Malaysia, Indonesia, Thailand, China, and Taiwan, with customers all over the world, mainly from Europe and the United States.

5 Overseas Locations

Each of their plants has its own specialty. The Vietnam and China plants specialize in carbon steel screws (the Vietnam plant focuses on small screws and self-drilling screws; the China plant focuses on large bolts); the Indonesia and Malaysia plants mainly produce stainless steel screws. The Vietnam plant started production 6 years ago, and the whole process including heading, threading, slotting, tail clamping, heat treatment, and plating are all completed under strict quality control in the plant. All aspects of the Vietnam plant have been well-established, and the number of orders continues to increase. See Table 1 for details.

Rest Assured for Stable Supply

from 5 Overseas Locations

In the midst of the Russia-Ukraine war and the tension in Asia Pacific, some European and American customers have asked Taiwanese manufacturers to find another production base in addition to their Taiwan bases. This concept is also termed as "Taiwan + 1".

In regard to this trend, Linkwell had been expanding its overseas plants for many years. With access to European and American markets as well as by having multiple overseas locations, Linkwell continues to automate production, lower their operating costs, and produce higher-value special products. This is why they can stick it out through political and economic crisis in the past half a century without crumbling and continue to provide a steady supply of fasteners.

Looking ahead to the second half of the year and next year, they will continue to be a one-stop fastener hub and strengthen collaborations with customers to create a better future together.

Contact: Ms. Paggy Chen / Email: paggy@linkwell.com.tw

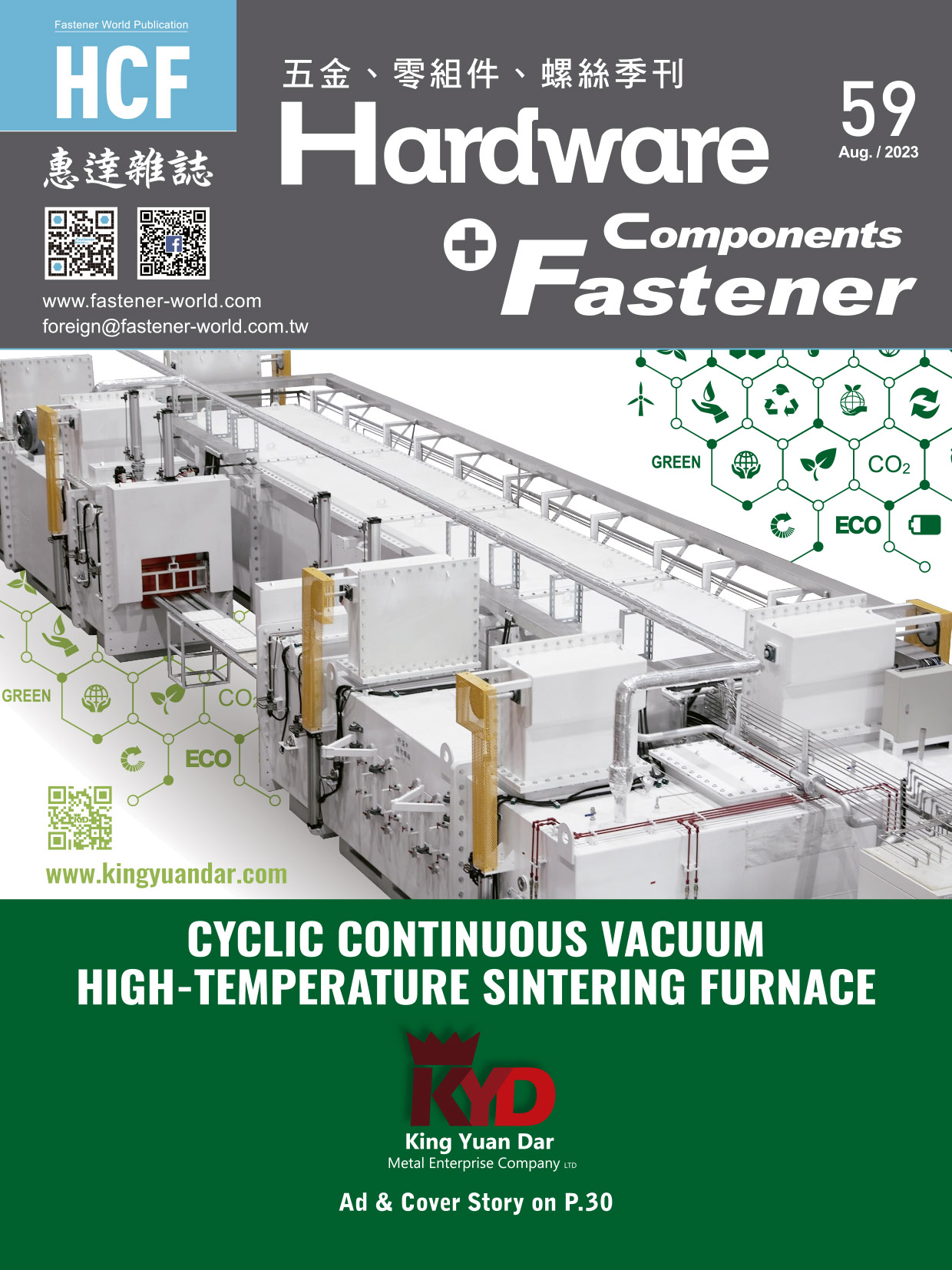

New Product! KING YUAN DAR Releases “Cyclic Continuous Vacuum High-Temperature Sintering Furnace”

Following the launch of the industry-shaking AI Continuous Batch Green Chamber Furnace and the world's leading AI Vacuum Continuous Cyclic Energy Saving Spheroidizing Furnace in early 2022, Taiwanese heat treatment equipment developer and manufacturer, King Yuan Dar Metal Enterprise Co., Ltd. (KYD), is once again taking the lead in launching a new "Cyclic Continuous Vacuum High Temperature Sintering Furnace" this year, which not only incorporates more excellent features, but also is designed with the concept of energy-saving and carbon reduction as the basis of its development. It is expected to create more amazing production efficiency and product quality for the global industries that have the need for product heat treatment (e.g. fasteners, industrial components, powder metallurgy, etc.).

Saving Energy and Reducing Carbon Emission; Highly Efficient and Eco-friendly

Developed under the guidance of KYD's GM Chang-Lung Tseng, the new equipment has several features:

Intuitive operation: Combining the interface of automation and intelligent hardware, the operator on-site only needs to arrange the material feeding and set values to operate.

Remote and AI monitoring: Management can be carried out through watching remote images. In addition, through the precise monitoring of AI intelligent system, operators can be reminded to check the temperature of the equipment in time when it is abnormal.

Power transforming system: Helping stabilize the power input to ensure normal operation of the machine.

Gas control system: It can properly adjust the ratio of gases in the machine to significantly increase the yield rate of workpieces produced.

Heat Recovery and Recycling System: The continuous production of the machine will transmit, convect, and radiate heat to the workpieces to achieve energy saving and carbon reduction.

High efficiency, environmental protection and power saving: As more waste heat is recycled and reused, the power consumption of the equipment is further reduced.

Multiply the capacity and stabilize the quality: Instead of using traditional mesh belts, this machine adopts hydraulic technology to convey parts, allowing it to operate more efficiently, thus doubling the capacity, but at the same time, maintaining the quality of products produced.

Recently Receiving an U.S. Patent for Heat Recovery and Recycling System

“Currently, no other equipment on the market has such core heat treatment technology and design similar to that of this new sintering furnace. Although 80-90% of our sales are in Taiwan at this stage, we expect to expand our global market share in the future by making more people aware of the application advantages of our equipment and one-stop service,” said GM Tseng.

In addition to obtaining the ISO 9001 and IATF 16949 certifications, the oxidation furnace structure, the chamber furnace structure, and the heat recycling system developed by KYD have been also patented in Taiwan, China, Japan, Germany, and the U.S. Its strong R&D capabilities have been internationally recognized and it has cooperated with customers throughout the fastener, automobile, motorcycle, and government sectors.

In the future, KYD will continue to dedicate itself to the development of environmentally-friendly AI heat treatment equipment and provide a 3-in-1 solution integrating heat treatment processing, gas supplies, and equipment manufacturing. In addition to the Luchu, Kaohsiung-based plant, the new plant based in Changhua Coastal Park is also expected to be officially completed by the end of this year, and the Thailand-based plant, close to local automotive supply chains, is expected to be operational next year after the installation of all equipment, which then will be a booster for KYD’s global deployment.

“My long-term goal is to enter the U.S. heat treatment market within two years, and then expand our sales in Taiwan to win a higher market share for our competitive equipment,” said GM Tseng.

Contact: General Manager Chang-Lung Tseng

E-mail: gold.dollar@msa.hinet.net