Klimas Fastener Technologies -Company and Fasteners with Strength for Generations

Klimas, a Polish manufacturer of fastening techniques with over 30 years of experience, dynamically develops sales of its products around the world. It provides a rich portfolio of products for professional construction applications, including solutions for the increasingly thriving segment of wooden structures.

KLIMAS is a leading Polish manufacturer of the highest quality fastening techniques. Thanks to the experience of high-class specialists, cooperation with manufacturers from various industries, new investments and dialogue with customers, the Klimas brand has for 30 years been synonymous with the highest quality fasteners used in the construction industry. Klimas brand offer encompasses a full portfolio of fastening techniques. It is a complete range of products designed for the widely understood construction industry, from fasteners for wooden structures and light constructions, flat roofs, window production screws, insulation plugs, as well as specialist fasteners dedicated to take. The manufacturer also provides universal solutions for the DIY sector. Not only the product itself but also service support in the field of calculations (e.g. load-bearing capacity or wind calculations), which it offers to customers at every stage of investment, plays an important role in the company's activity.

Modern production facilities and quality control

Thanks to modern production facilities, the company is independent at every stage of product development. The four production plants, with a total area of more than 80,000 m2, are among the most modern manufacturing facilities of fastening techniques in Europe. Thanks to the technologies and applications used here, they are ready for Industry 4.0. The equipment of the plants includes several hundred machines, tool room with advanced machining centres, high storage warehouse and modern quality control department, meeting the highest requirements of the domestic and foreign markets. Quality control is a standard part of the production line before packaging. Each product goes through a series of detailed tests. All tests are aimed at maintaining the highest quality, which affects the safety during the use of products. The company regularly undergoes external and internal inspections, which is confirmed by numerous certificates.

A higher level of cooperation

The company carefully follows the trends, demand for products, so as to properly adjust the offer to a given country. Good, long-term relationships, developed at foreign fairs, as well as adaptation of production to international technical requirements resulted in the fact that today the manufacturer delivers its solutions to 60 countries in the world and continues to expand the portfolio of foreign customers. The company builds sales based on its own companies or cooperation with trading partners. In India, France or the Czech Republic, Klimas has created a sales team that makes sure that the product range reaches large investments. The company's own branches, with fully equipped showrooms, allow direct contact with customers, but also give the opportunity for training and presentations. At the same time, the company has established cooperation with many business partners who are also developing the Klimas export brand on world markets.

Investment in development

The manufacturer continues to develop its offer not only by increasing its product portfolio but also by continuous product improvement. Based on the modern research and development centre, the company creates new solutions for its customers, which then become one of the best products on the market from the technical point of view. Klimas has introduced into its offer, among others, a modern SQ Ceramic solution i.e. lamellar coating characterized by extremely effective protection against corrosion, despite relatively thin layer. The latest solutions developed by Klimas experts include a new milling tip in the field of wood screws, which speeds up screwing even by 40% with 20% less pressure. Intensive development works are also carried out in the sphere of specialist products, such as screws for concrete or express mechanical anchors. In the case of products from the family of mechanical anchors, Klimas offers a dedicated tool for the calculation of fixings. The free Wkręt-met DesignFiX application is aimed at providing maximum support for designers, engineers and contractors in the design of structures in accordance with investment requirements.

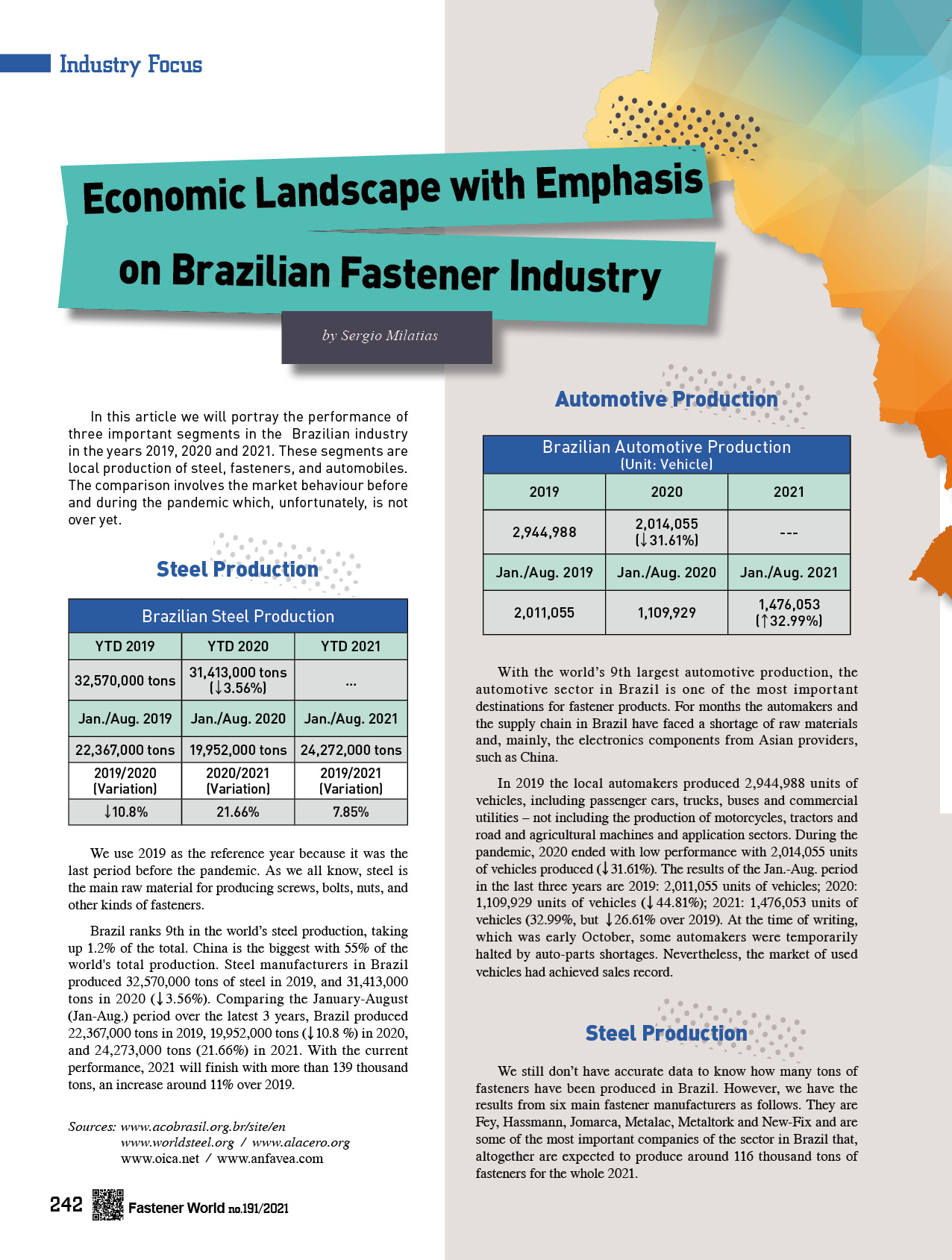

Wood construction screws - the answer to the requirements of modern wood construction

Today, wood is one of the most important renewable building materials, and its use in construction can significantly contribute to minimizing environmental degradation. Moreover, the properties of wood translate into usable values of buildings. That is why there is growing interest in this raw material all over the world. In order for wooden structures to maintain the character of sustainable construction, which does not cause irreversible damage to the environment, they must be durable. Durability of each structure depends on all its elements including fixings. In this field, Klimas offers solutions in the form of a family of construction screws, the use of which affects the durability of buildings.

Among contractors, wood screws owe their popularity to their advantages, which include, above all, transferring greater loads, comfort and speed of fastening, making it possible to tighten screwed elements, increasing the rigidity of fastened elements and, finally, making it possible to correct faulty assembly (the possibility of unscrewing and re-screwing). One of the most popular products with universal application are construction screws with a washer head (WKCP) or a countersunk head (WKCS and KMWH). Properly selected material (carbon steel), refined heat treatment and special thread geometry give these screws high strength parameters. Therefore, they perform well both in fixing insulation, reinforcing structures or repairing them as they improve the shear resistance of beams (screwing at an angle makes the screws take up loads better, which in turn increases the load on the beam itself).

Wooden structures, such as rafter framing requires very high precision of workmanship, especially in the area of connections of its individual elements (rafters, rafter tubes, purlins, clamps, swords, posts). That is why fastening details that allow professionals to precisely finish the connections are so important. The manufacturer responds to market needs by offering WKSS distance screws, which facilitate the process of levelling surfaces in wooden structures. A typical application of these screws is levelling battens in roof constructions and levelling the surface of external façades.

Fast and safe screwing of construction screws is guaranteed by the innovative tip design and additional cutting notches. Their role is to cut through wood fibres during screwing, so they can be installed without pre-drilling. The screw heads have special TX hexagonal sockets that hold the screwdriver bit securely and guide the screws more precisely. This means that the screws can be screwed in with greater precision with less effort. Depending on the corrosion requirements, all screws can be either galvanised or protected with SQ Ceramic coating, which provides corrosion resistance up to class C4. In addition, screws with galvanised protection are additionally provided with a special wax coating, which significantly reduces the screwing torque. This makes assembly faster, easier and reduces battery consumption.

The manufacturer declares that all products have been tested by external accredited laboratories before being placed on the market. ETAs are on the one hand a confirmation that the product meets the requirements of the European Union with respect to its application, but they also mean additional, permanent obligations for the manufacturer. The manufacturer must strictly adhere to the established standards for manufacturing, storage and distribution of the product and conduct continuous monitoring of the production process. Klimas brand products are appreciated for their durability and complexity by installers. One of the most important elements necessary for the creation of ideal screws is listening to the needs of the market. As a result of cooperation with partners and customers and through countless tests and quality control at every stage of production, it is possible to create fasteners fully adapted to the modern market.

https://www.klimas.com