CHIN TAI SING PRECISION MANUFACTORY

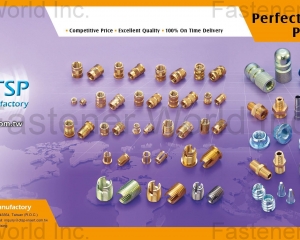

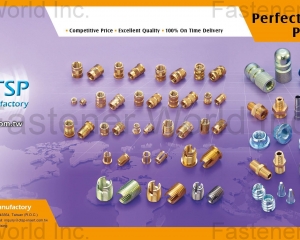

Chin Tai Sing Precision Manufactory is one of the most professional manufactory in Taiwan who offers various precision plastic mold in Brass Insert and Clinching Metal Fasteners for Pre-heating, Ultrasonic and Press-in, Screw-in. CTSP Manufactory formed by several professional staffs who have over 20 years production experience from several reputed brass insert, CNC and metal parts manufactories in Taiwan. It owns the best technical staffs, experienced manufactory operators and outstanding foreign sale specialists.

The best technical staffs in CTSP provide our customer the best quality parts with our special OEM and ODM services. We provide the best Quality Control system to make sure that every part from CTSP is the best and perfect in order to provide our customers the most competitive quality on the market.

The best experienced manufactory operators in CTSP provide their great ability to connect the factory department, QC department and our sales department. They used their great experience to make all procedures work fluently. This can save unnecessary cost that might incurred when connecting the factory and sales. The unnecessary cost that we saved, we will reflect to our selling price and benefit to our customer in order to provide our customer the most competitive selling price on the market.

The outstanding foreign sales specialists in CTSP provide their great English ability and their perfect services. This will avoid the problem of the communication between our customers and also shorten the distance between Supplier and Customer. CTSP will not just provide our best goods and services to our customer but also wish our customers become our partner and growth with us, beat the competitor with us.

With those great supports from our factory department and sales department in CTSP, we can provide our customer the following production services.

Treating Every Customer’s Order as with 0ppm Requirement,

CTSP Manufactory Reinforces Deployment in Global High-end Markets

Founded decades ago, Chin Tai Sing Precision Manufactory (“CTSP”) has had its main business focused on OEM production for standard parts as well as bespoke brass inserts, metal clinching fasteners, and components in stainless steel, aluminum, and various materials, and has become an automotive and electronics parts supplier recognized by global high-end industries. It has not only been certified to both ISO 9001 and IATF 16949 international quality management systems, but also has consolidated a firm presence for years in European/U.S./Japanese high-end markets with its years of excellent manufacturing capabilities, a well-experienced team for marketing and sales, and highly competitive performance-to-price ratios on the market.

Strict Quality Control Beyond Customers’ Requirements

The monthly capacity of CTSP quickly jumping from the initial 10 million pcs to 20 million pcs within just a few years did impress its business partners from European/U.S./Japanese high-end markets a lot, and the key factors of this success lie on CTSP’s strict manufacturing & quality control procedures, state-of-the-art automated equipment, and highly systematic production management with batch codes.

With the strict monitoring of senior technicians having more than 20 years of experience, CTSP can ensure the compliance with ISO 9001 and IATF 16949 international quality management systems of every part being processed in its fully automated equipment. Meanwhile, in order to meet the requirements of customers’ orders, CTSP attaches importance to every detail a lot. It introduced image measurement instruments and optical sorting machines to inspect dimensions and specifications, and utilizes automated sorting and packaging machines to keep seamless quality control from the very beginning of manufacturing to final delivery.

CTSP’s strict requirements and confidence in product quality can be also observed in its service provided to customers. For example, its team will always meet together to find out the most suitable solutions for quality anomaly, manufacturing optimization, and new product inspection. Furthermore, in order to keep customers updated with real-time production status at all times, every product of CTSP will be given a batch code with traceability. It can also provide customers with valid documents for material certification, RoHS certification, PPAP, IMDS, ISIR, etc. if needed.

CTSP General Manager Johny Lee said, “In order to offer good quality, we must not only have quality inspectors and precision equipment to carry out strict quality control, but also must hold a firm attitude toward it. Our requirements for quality are not only focused on finished products, but also focused on the procedures of material feeding and all manufacturing procedures. We often assume that all of our customers require 0ppm in their orders placed to us and try our best to meet or even exceed their requirements for quality, provide them with products at competitive prices, and make them have confidence in the quality of our products.”

Targeting High-end Industrial Users and Expanding Efficient Service

Despite the fact that CTSP has been widely recognized and accepted in European, U.S. and Japanese high-end markets, CTSP still believes that it should accelerate its steps toward more advanced markets and industries and cultivate unbeatable strength to face possible market challenges in the future. General Manager Lee added, “Taiwanese hardware related industry is currently facing the problems like severe labor shortage and the inability to increase capacity, so CTSP will increase more automated production and inspection equipment to achieve the optimal capacity and quality according to each customer’s demand. In this way, we can improve our production performance, save the labor cost, and increase the yield rate. We will also develop more precision products (within the tolerance of ±0.01) to serve customers from more advanced industries.”

Contact: General Manager Johny Lee

* Clinching Metal Fasteners (Clinching Nuts, Studs, Blind Standoff and Standoff)

* Customer Design Parts with various material such as Stainless Steel, Aluminum etc.

To present the best quality parts to our customer, we have ISO Certificate and also perform the requirement of TS16949.