Industry Activities

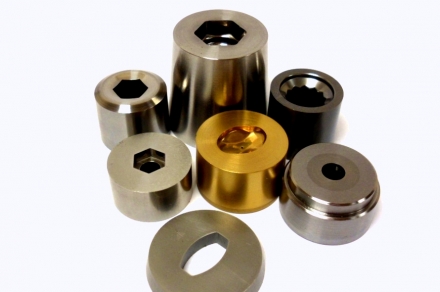

Established in 1973, the Birmingham, England based CTR Carbide Dies is one of the largest ing. With a team of 40 skilled engineers and other well-talented multilinguistic sales professionals, CTR Carbide Dies is able to supply a complete portfolio of standard and specialized fastener tooling and dies made of a wide range of materials such as tungsten carbide in grades G6 to G30 and export to its customers worldwide in more than 50 countries.

Seven Decades Expertise in Fastener Tooling and Metal Machining

CTR, originally focusing its main business on automotive supply, has gradually extended its product coverage in recent years to aerospace, railway, medical, energy, defense and many other market sectors, in order to fully satisfy demands of customers from various industries. Boasting over 75 years expertise in the fastener industry, the management team of CTR continues to maintain close working relationship with customers, which, according to Peter Ruitenberg, Sales & Marketing Manager of CTR, enables them to “offer added value tool design and 3D development modelling resulting in cost savings by reducing process operations with the benefit of extended tool life.”

By having the strictest manufacturing process and quality inspection controls in place, CTR could offer fastener tooling that meets the highest industrial standards and requirements, which have been also widely used in manufacturing fasteners of industrial standards or special specifications including airframe rivets, anchor bolts, wheel bolts, engine bolts, special formed gear assemblies and alloy nuts.

Full-range Customer Support, Complete In-plant Equipment & Approved Certification

In addition to the manufacture of fastener tooling and dies, CTR also has a unique customer support facility from rapid turnaround for modification/refurbished tooling to a comprehensive CAD/AUTOCAD die design consultancy service. CTR was certified to ISO 9001 in 2004 and was later certified to AS EN ISO 9100 aerospace standard in 2007. The quality system of CTR has been also recently re-certified to BS EN IS0 9001:2015 and AS 9100 Rev D.

Mr. Ruitenberg added, “We have proven experience in low volume sub contract machining such as tooling for spring manufacturing, tube cold forming dies, feed fingers and various other component part machining. Our portfolio of machine tools includes Mill Turn CNC Lathes, CNC Internal Grinding Machines, two 5 Axis machining Centres all complemented by the latest technology in Wire and Spark Electrode Discharge Machines.” All of these show the involvement and endeavors of CTR manufacturing group to offer customers the highest quality and the most comprehensive products and service.

According to the management team of CTR, the company, being an active contributor to the R&D of fastener tooling and dies, will continue to make endeavors to fulfil the “Complete Tooling Requirement” of customers as its objective, because, as the entire team of CTR always believes, “it is not only the quality of life that we all come to demand and expect, but also the life of quality.”