Industry Activities

Headquartered in Hunei (Kaohsiung) and established in 1998, Ry Maw Precision Tooling Co., Ltd. has been in the business for nearly two decades. For years it has continuously built up close relationship and collaboration with the fastener industry and has become a precision tooling supplier for global fastener manufacturers. With an excellent technical & sales team and integrated management & operation systems, Ry Maw specializes in the production of customized punches for fasteners and can produce as per customer’s drawing, effectively achieving the precision and stability required by customers. Its eye-catching performance, durability and effectiveness of products has won itself an industrywide admired reputation.

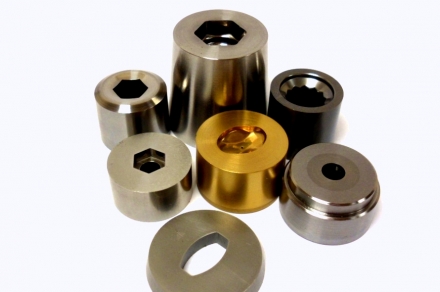

100% Customization, Giving a Boost to Customers’Products

The customized product portfolio of Ry Maw currently includes Punch Parts, Stamping Punches, Square Punches, Socket Punches, Hexagon Punches, 12-PT Punches, Customized Punches and Sleeves, mainly made of high speed steel and tungsten steel, which could be also electroplated upon customer’s request. Inside the plant of Ry Maw are also installed with Micro-Hite 350, Rockwell Hardness Test AR-10, Projectors PH-3500/PJ-A3000/PH-3500, Surface Roughness Machine SJ-301, 3D Measuring Instrument CW-3020-CNC, Contour Measuring Instrument CV-500 to ensure that the quality of all punches is fully compliant with relevant standards.

“Being a humble solution provider for customers” has been for long the mission statement of Ry Maw. Knowing that every customer’s demand is different, Ry Maw develops its own unique one-on-one project for punch development. Through the complete SOP that helps achieve accurate processing time control, dimensions, and completeness, every piece of punch delivered from Ry Maw can be 100% compliant with the requirements of every customer’s drawing, thus eliminating the issues generated by inferior quality like unexpected halts of production lines, cost hikes and shipment delay. Ry Maw, since its inception, has dedicated itself to product processing for Japanese customers and maintained long-term collaboration with traders. Its customers are not only from the domestic Taiwanese market, but also from overseas markets like Europe, USA and Japan.

ISO 9001 Certified, Ry Maw Never Stops Until Perfection

If we review Ry Maw’s history in the past 20 years, we could see that Ry Maw reached a new stage almost every few years. For example, it was established in 1998; its plant was expanded in 2001; the first relocation was completed in 2005; it integrated scrapped material recycling system in 2006; it was certified to ISO 9001 in 2009; and most recently, its new website was activated in 2016. “Our progress is still ongoing, as we hope to offer the best products to customers and make them create more added value with our products. Our business philosophy is: Good relationship with customers, highly demanding quality, international vision, morality is a virtue, and employees are our wealth. On the other hand, we are also dedicated to diversifying our product range and improving their service life and quality. We regularly examine our procedures with ISO and PDCA systems, continuously acquire new knowledge and make improvements in order to provide much more market uniqueness. Our non-stop growth in technical achievements is the best proof of our eagerness to respond to customers,” said General Manager Sung Ming-Hsien.

Outperforming with Profession, Ry Maw Aims at Orders from Tier 1 Customers in Europe/USA/Japan

Ry Maw’s wealth of knowledge and experience in punches make it able to fully control the manufacturing procedures, thus completing tasks as scheduled, achieving required modulus and allowing customers to launch immediate production upon receipt. Looking forward, Ry Maw has had its own blueprint ready. GM Sung concluded, “We wish to be the supplier for T1 customers and add in our orderbook with more requests from Europe, USA and Japan within a few years. Moreover, we also wish to strengthen and keep stable relationship with customers and solve

Subscribe