Industry Activities

TWINNUT GmbH was born out of president Dietmar Schnier’s idea to create a simple separable nut device. It sells the patented TWINNUTs to resellers and solution providers. Its core business is all about quick clamping, fastening, and pre-assembly if the ordinary means and tools are either impossible or too costly. To this date, it has achieved a decent level of cost awareness among mechanical, operational and maintenance engineering specialists. It has produced and shipped a few hundred thousands of TWINNUTs. “Germany, Austria, Switzerland and the Benelux region are our strongest markets. We see rising interest and requests from the Nordic region, UK, US and Canada. We give best services to all international customers once they have claimed their interest in TWINNUT,” said the president.

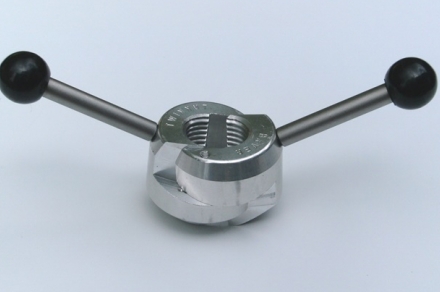

The Award-winning TWINNUT Structure

The key concept of TWINNUT is the curved contact surfaces on two parts. It has to be designed with specific parameters depending on certain geometric properties, including the thread. The result is strength class 10 or higher for a 42CrMo4 collared TWINNUT applicable to static applications and dynamic loads. For easy handling, a separation lock is integrated to prevent the two parts from falling apart, but TWINNUT can be completely separated by ordinary manual force and be re-combined again. It is available in 42CrMo4 (heat treatable), V2A (anti-corrosion), Teflon coating, brass, aluminum, nylon, glass-fiber reinforced plastics, etc. and in sizes M6-M80, and can be equipped with a handle for easy handling. “A successful example is its application to counter or jam nuts. Applying initially forgotten counter nuts after setting up the machine does require huge efforts and causes long and painful downtimes. In this case a TWINNUT solution is a serious option. Just think about how many minutes saved per single execution compared with the typical costs for industrial labor, and estimate the number of repetitions per shift or day. The result is a tremendous saving which compensates for the cost of TWINNUTs in a few months or weeks,” explained the president. TWINNUT was awarded by iF Design, M Technology and DESIGNPREIS. “It was a proof-of-concept for TWINNUT, not just through design but also for technical aspects. This gave me important confirmation to believe in the product and its future position in the markets.”

Market & Business Outlook

“We are in a quite comfortable and relaxed situation due to our manageable size and organization, commercial volume and the fact that we service the markets undisputable with niche products and solutions, even though they are top-notch and fairly unrivaled.” At the upcoming Fastener Fair Stuttgart, the company will feature the super large M80 TWINNUTs and its application in underwater pre-assembly for tidal power stations and wind power stations, as well as TWINNUT separable cap nut used on hydraulic piping devices in chemical and other processing industries. The company plans to find new applications for hexagonal TWINNUTs, implement TWINNUTs on OEM devices, and expand collaboration with distributors. “We are always open for discussion with competent re-sellers and distributors whose portfolio and our niche product may fit. Finally, we are willing to discuss license assignment to suitable companies and organizations.”

Subscribe