Industry Activities

by Tanya Shih, Fastener World

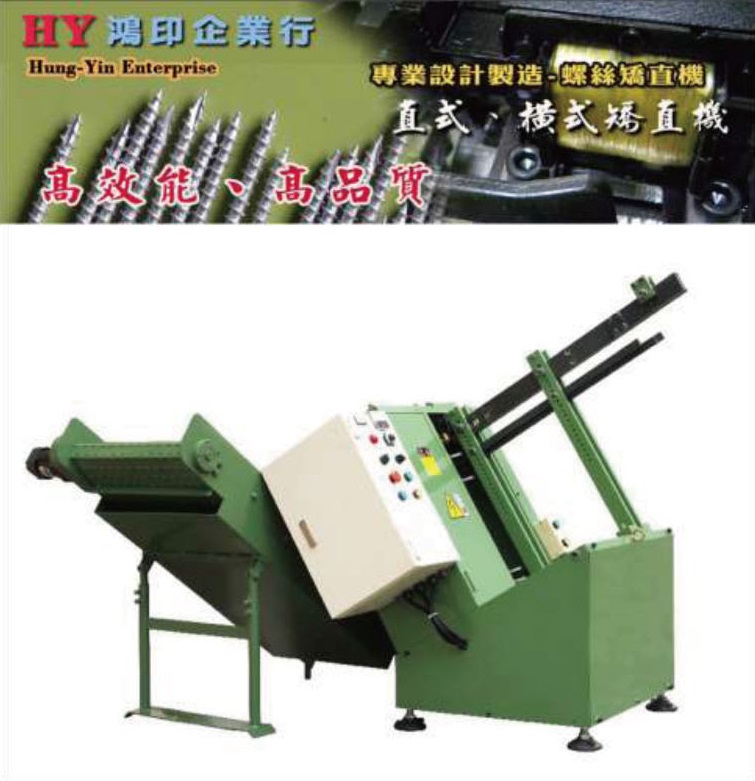

General manager Wu-zhang Chang of Hung-Yin Enterprise developed a screw straightening machine as a replacement for conventional hydraulic straightening machines. The conventional models could only process 8-10 pcs per min., but the new model of Hung-Yin can straighten 50 or more pcs of long screws per min. (i.e., over 20,000 pcs per 8 hours). This model with highly efficient performance is becoming more and more popular around the global fastener industry. This new straightening machine has been patented in Taiwan, China, Korea, Vietnam, and Malaysia. 2 years after its debut, Hung-Yin still maintains the sales of at least 5 sets per month. On the day of this interview, general manager Chang was still busy in arranging the power distribution of the straightening machines which were almost ready to be shipped to Poland and Turkey.

A Layman Who Knows the Fastener Industry Well Gets a “Wow” from the Market

It has been only 3 years since Hung-Yin switched its business focus from knob molds R&D to fasteners and it did not take too long for its straightening machine to overwhelm the market, which thus encouraged Chang to seek further growth. So far, Hung-Yin has moved from a small 66m2 manufacturing site to a larger 397m2 factory which can accommodate 6 sets of straightening machines. It also plans to move again to a larger 6,611 m2 new factory and will continue to offer straightening service to fastener manufacturers in Gangshan. When the construction of the new factory is completed, Hung-Yin will have an enough manufacturing site for straightening machines before they are assemble and ship to customers.

Hung-Yin’s remarkable performance makes people curious about why a layman that started his business in a non-fastener industry could finally make a success in the fastener industry. “Customers voices are what we care about,” said Chang. Many Taiwanese knob manufacturers had relocated factories abroad, so less demand for knob molds directly impacted Chang’s previous business. Noticing the potential demand from Taiwanese fastener market and customers’ demand in manufacturing process, Chang with 25 years of experience in molds development then devoted himself to the fastener industry and developed a precise and highly efficient straightening machine 3 years ago.

Excellent Performance That Draws Leading Manufacturers’ Attention

Compared to other oil-pressure straightening machines, this new model is automatically controlled from feeding to straightening and is applicable to materials like steel, copper, aluminum, and iron, without damaging shanks and threads. 3 machines can be operated by only 1 man, which can greatly reduce the labor and time costs. Manufacturers adopting Hung-Yin straightening machines can temper long screws with less expensive continuous furnaces and the benefits it creates include not only lower manufacturing costs, but also shorter lead time as well as better quality control, best satisfying customers’ demand.

Hung-Yin specializes in design and manufacture of straightening machines. In addition to the existing standard straightening machines, it can also manufacture other straightening machines and vibratory machines for certain lengths and diameters as per customer’s requirement. Hung-Yin earned its reputation in the market within 3 years. Leading fastener suppliers like Jau Yeou, Dra-Goon, Kwantex, and even fasteners from Germany are all its service targets.

Subscribe